Rogerio dos Santos

Rogerio dos Santos

VP of Strategy & Portfolio Management

____

JLG Industries

Applications and uses for articulated boom lifts are fairly well established — mostly in industrial construction, maintenance and repair tasks, as well as in congested spaces, like in urban areas and city centers, that require operators to access to multiple angles and reach in order to complete work at height.

There’s also been an increase in the use of these machines on bridge-building and repair projects near busy highways and intersections.

Overall, market demand for articulated boom lifts is high right now, and we expect it to remain up for the foreseeable future thanks to the post-pandemic project backlog, as well as new work just getting started because of the infrastructure bill. There is plenty of work to do right now, and there are no signs of it slowing down.

Let’s look at what trends are influencing the articulated boom lift market right now, and how JLG is responding to users’ needs…

What changes, if any, are coming to the articulating boom lift market in the coming year(s)?

Job site scenarios that are time-consuming and impede performance drive innovation at JLG across all our product lines. You’ve seen some examples of this in our recent introductions, like our 670SJ telescopic self-leveling boom lift and our DaVinci® AE1932 all-electric scissor lift. We will continue this trend, introducing new technologies and innovative products throughout our entire portfolio, including in our articulating boom lift line, in the coming years. For example, continuous improvement in user operability and job site connectivity are major focal points as new technologies become available. These solutions will truly transform how people work at height by increasing productivity and enhancing safety best practices.

One of the biggest trends within the articulating boom sector is the move toward hybrid and/or electrification power sources. What’s going on with “green” advancements in the market?

We see the move toward non-fossil, fuel-based (hybrid or electrified) articulated boom lifts being driven by the increasing use of these machines in urban environments, with increasingly stringent regulatory requirements, primarily with carbon footprint. Not only is urbanization is resulting in less open space on and between job sites, which drives greater demand for high-reach equipment with a compact footprint, but it is also creating a socio-economic impact, too. As younger and younger generations enter the system, they're demanding more social responsibility from an environmental standpoint. As urbanization has increased people’s awareness of environmental issues there are now more emission-free zones and a call for more fossil fuel independence from almost a geopolitical standpoint, driving greater demand for electrification.

How are battery runtimes and technology influencing the articulated boom lift market?

Battery runtimes, regardless of model brand or size, are dependent on the application. Our customers are looking for articulated boom lifts that can run a full work shift without needing to stop to recharge the battery, no matter what terrain the machine is working in or how many duty cycles the operators have completed (to name a few factors and variables that influence battery life).

Historically, our machines have been equipped with flooded-lead acid batteries (FLA) that boast industry-leading run times. But as battery technology advances and the costs become more affordable, we are shifting our products toward lithium-ion battery sources that will offer longer runtimes and reduced charging times, thereby increasing JLG machines’ utilization throughout the workday.

Even if electric booms can run an entire shift on battery power, it must be charged before the next user takes the controls. Charging solutions is a hurdle the industry faces – what’s being done to address this?

One of the biggest challenges threatening adoption as more equipment goes electric is how these machines will be charged on-site by users, particularly in the early stages of construction or in remote locations where power is not readily available. Right now, the big gap in the electrification ecosystem is the charging infrastructure, and everyone is working on different ways to address it.

At JLG, we are looking to provide solutions in phases to address this, from portable charging stations short-term to developing temporary fixed installations near-term and building permanent fixed installations for future, long-term use.

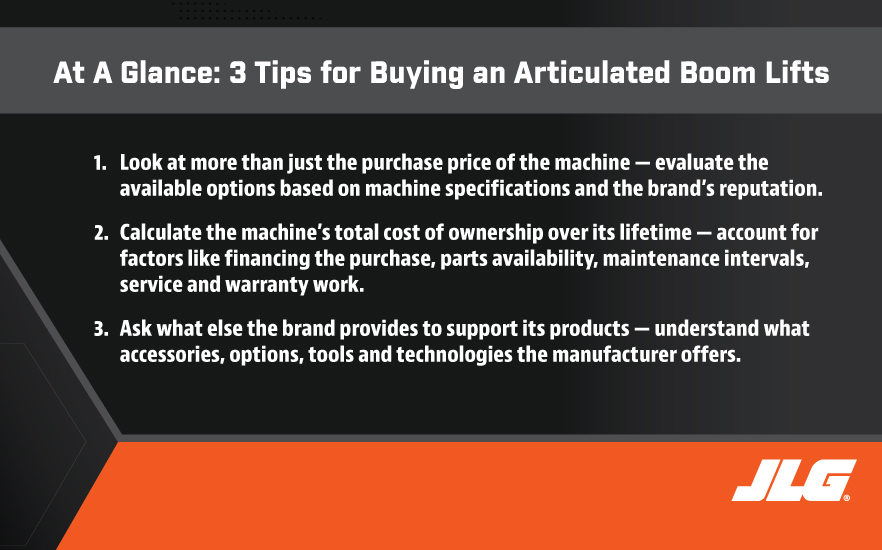

What are three tips you can provide to articulated boom lift buyers to help them make a purchasing decision?

As users are looking to purchase new articulating boom lifts, we suggest following these three steps when making their decision…

First, look at more than just the purchase price of the machine. Fleet managers should consider everything from their budget to the specific tasks that will need to be completed with the machine. For example, having too much — or too little machine — can present challenges. It is important to evaluate the available options based on machine specifications like stability and capacity, as well as the brand’s reputation for reliability and safety.

Second, calculate the machine’s total cost of ownership over its lifetime. Fleet managers should account for factors like financing the purchase, parts availability, maintenance intervals, service and warranty work, telematics and digital tools to manage the equipment, operator and technician training and resale value of the brand.

Third, ask what else the brand provides to support its products. Fleet managers should understand what accessories, options, tools and technologies the manufacturer offers to enhance the users’ experience with its equipment. Also, fleet managers should be able to access the information they need to know for successfully owning and operating an OEM’s articulated boom lift.

What sets JLG articulated boom lifts apart from competitors’ models?

On the job site, days are measured by productivity, which means our customers expect equipment that stands up to the day’s demands. JLG engine-powered articulating boom lifts and electric/hybrid articulated boom lifts are field-proven to put in the most productive day possible. Whether on slab or off, JLG articulating boom lifts provide performance and reliability, featuring larger work envelopes, enhanced capacities and industry-leading reach heights with exceptional terrainability and gradeability.

And as the world’s leading designer and manufacturer of access equipment, JLG personnel can be found all over the world, going above and beyond to support customers. We not only deliver the powerful, versatile equipment they need, but we also provide unsurpassed training and service — because we have a responsibility to be more than a manufacturing company. We’re a partner in our customers’ success, reaching out worldwide to enable performance, boost productivity, ensure uptime and support forward progress.

For an in-depth look at JLG’s articulated boom lift line-up, click here.

Do you want to stay up-to-date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from #DirectAccess with newly posted content so you never miss important information.