Misty Mason

Misty Mason

Product Manager, Low Level Access

____

JLG Industries

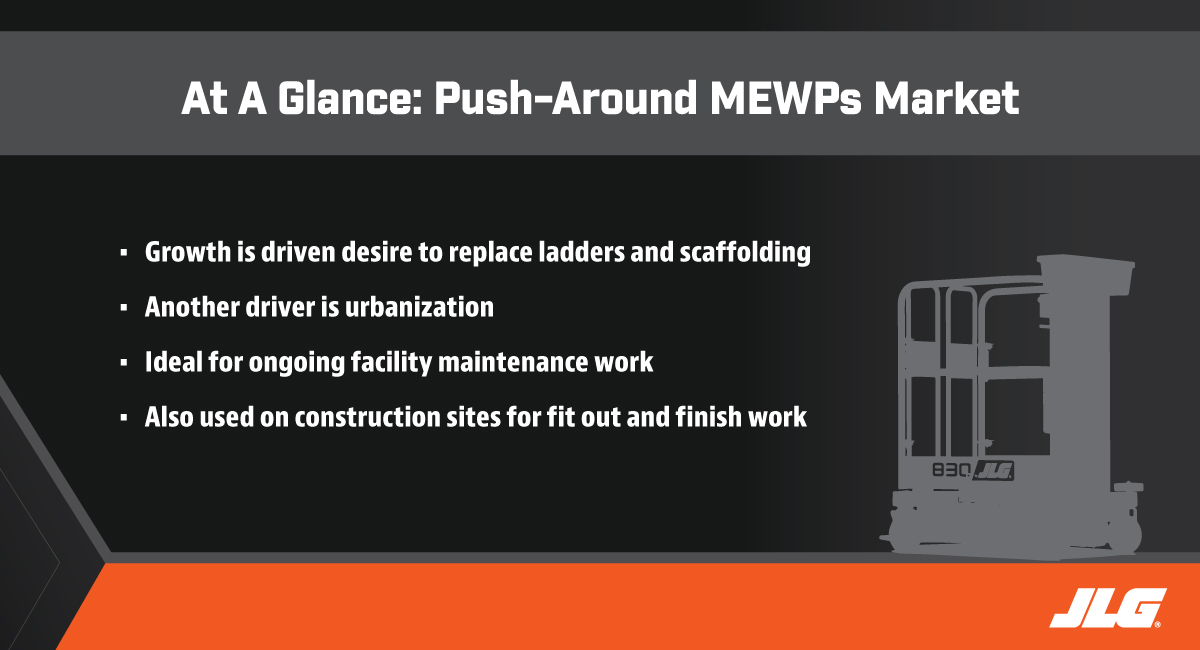

Popularity for push-around lifts, or mobile elevating work platforms (MEWPs), has been increasing in the past few years. This growth is driven by applications where workers might have once used ladders and scaffolding. That’s because more and more companies are looking for safer ways to work at height.

Another driver behind the growth is urbanization. With less open space, and buildings getting taller and narrower, there is a greater need for products that have a small footprint, are lighter weight for use on sensitive flooring, that can fit into in elevators and can be moved between floors for finish and fit out construction work or ongoing maintenance.

What are some tips/factors users should consider when choosing a push-around MEWP?

As with any equipment selection, when choosing a push-around MEWP, owners or renters should consider the work to be done, including the height requirements of the job and the capacity that the lift will need to support, including the personnel, materials and tools that will be needed when elevated. Other key specifications to know are the maximum platform height, maximum working height and weight of the machine.

Other factors to consider are the constraints of the work area, such as narrow doorways, elevators, sensitive flooring and/or noise and emissions sensitivity. Also, it is important to know whether the machine will be working indoors or out, as many low-level access lifts are only rated for indoor use.

What are some of the recent advancements made to push-around MEWPs?

Advancements in push-around MEWPs have been focused on enhancing the operator’s experience through productivity-focused features, such as the inclusion of tool trays for the convenient storage of tools at height, the addition of saloon style doors and a step for easy access into and out of the platform. And in the case of the JLG EcoLift Series, the development of a patented stored-powered lift/lower system eliminates the need to charge a battery during or between shifts.

Low-level lifts are also designed to reduce strain on the body and lessen the risk of musculoskeletal injuries caused by repetitive movements, such as climbing up and down a ladder.

What are some of the trends influencing the push-around MEWP market?

As mentioned previously, these type of low-level access lifts can be used in a variety of work environments as a replacement product for ladders or scaffolding. For example, push-around MEWPs can be easily rolled through a facility and assembled or disassembled quickly, allowing workers to access catwalks, landings and other hard-to-reach areas. These lifts are ideal for applications including mechanical and electrical work, HVAC and ductwork, hanging drywall, painting, retail refit and display, construction finishing work and cleaning.

And, the EcoLift Series offers an eco-friendly solution with no batteries, hydraulics or oil. Because no hydraulics or motors are involved, these lifts are leak-free and operate quietly, making them a preferred piece of equipment for work in environmentally sensitive areas, such as clean rooms and data centers, as well as in hospitals, schools, libraries and office buildings where noise restrictions exist. They are simply hand cranked by the operator to access the work area.

Are there any new applications where push-around units are being used?

Because these types of machines are lightweight and compact in size, they can be easily pushed into place or between work areas and require minimal storage space, making them ideal for ongoing facility maintenance from airports to data centers to high-rise buildings — and just about anything in between.

Additionally, they are used on construction sites for fit out and finish work, such as painting, installing fire alarm or sprinkler systems, putting in (or replacing) lighting and ceiling tiles, as well as other similar tasks.

What’s driving market demand for these types of lifts?

We anticipate that demand for these will continue to grow as companies place more focus on replacing ladders and scaffolding in the workplace. They will also gain favor among companies focused on eco-friendly solutions and sustainability.

JLG has continued to expand its product line to meet this demand with the EcoLift™ 50 and EcoLift 70 human-powered lifts, as well as the 830P and 1030P push-around lifts. For more information on JLG’s low-level access solutions, click here.

Do you want to stay up to date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from #DirectAccess with newly posted content so you never miss important information.