Bob Begley

Bob Begley

Director - Product Management

____

JLG Industries

When it comes to compact mobile elevating work platforms, or MEWPs, (Please note: “Compact” is defined by AEM as 34- to 46-in wide machines.

Machine with widths up to 34-in are classified by AEM as “Slim” models), the two most important specifications that drive machine design and utilization in this size class are 1) How high the lift goes (i.e. maximum lift height), and 2) how much it weighs (i.e. gross vehicle weight).

Although the machine’s ability to pass through a single doorway is also a key metric to consider, other metrics that are equally as significant include: The number of people the platform can carry to height, the machine’s outside turning radius for fit and maneuverability in space-restricted areas and its ground-bearing pressure for work on sensitive flooring.

The biggest benefit of these lifts becoming more compact is that they can fit into more spaces and be used in more places to get work done, increasing users’ opportunities for working in new applications and increasing machine utilization.

But, the trade-off is: The more compact they get, and the lighter weight they are, the more the machines’ stability is influenced. To achieve narrower machine chassis and/or lighter weight designs, manufacturers have to compensate by adjusting other specifications, such as rating the machine for indoor use only or restricting its working height in certain conditions, to meet the industry standards for stability and safe use.

Let’s do a deeper dive into these types of MEWPs…

How have you seen the regional and overall market for compact MEWPs develop recently?

There is hypermarket demand globally for all types of MEWPs, including compact, right now thanks to the post-pandemic project backlog. And, we anticipate it to remain high for the foreseeable future — there is plenty of work to do, and there are no signs of it slowing down.

Demand does vary by region, for a variety of reasons, but despite regional differences, the applications and uses for compact lifts continue to grow, especially in urban areas with less open space and buildings that get taller and narrower. This creates a greater need for products with a small footprint, lighter weight for use on sensitive flooring, can fit into elevators and can be moved between floors for finish and fit-out construction work or ongoing maintenance.

Electric models are also gaining global favor as more regions regulate eco-friendly solutions for sustainability. For example, fully electrified models like the JLG® DaVinci® AE1932 all-electric scissor lift offer a “greener,” cleaner solution thanks to having no hydraulics or oil — these lifts are leak-free and operate quietly, making them a preferred piece of equipment for work in environmentally sensitive areas, such as clean rooms and data centers, as well as in hospitals, schools, libraries and office buildings where noise restrictions exist.

Is there an opportunity to take more weight out of compact MEWPs, making them lighter still?

The majority of weight in these machines comes from steel, which not only shapes the machine but also offers the necessary counterweight to achieve stability requirements. Opportunities to take out more weight are dependent on designing and manufacturing models with less steel.

That said, as mentioned in the previous response, achieving a lighter weight machine is a give and take with the machine’s height — decreasing the machine’s weight impacts its tip angles and stability. For safe use, the less it weighs, the more limits there are to the machine’s functionality.

What are JLG’s most popular compact lifts and why?

JLG’s three 19-ft scissor lift models, including the R1932, ES1932 and the AE1932, continue to be the universal go-to size for the industry for compact MEWPs because they meet the needs of multiple jobs and can be easily transported.

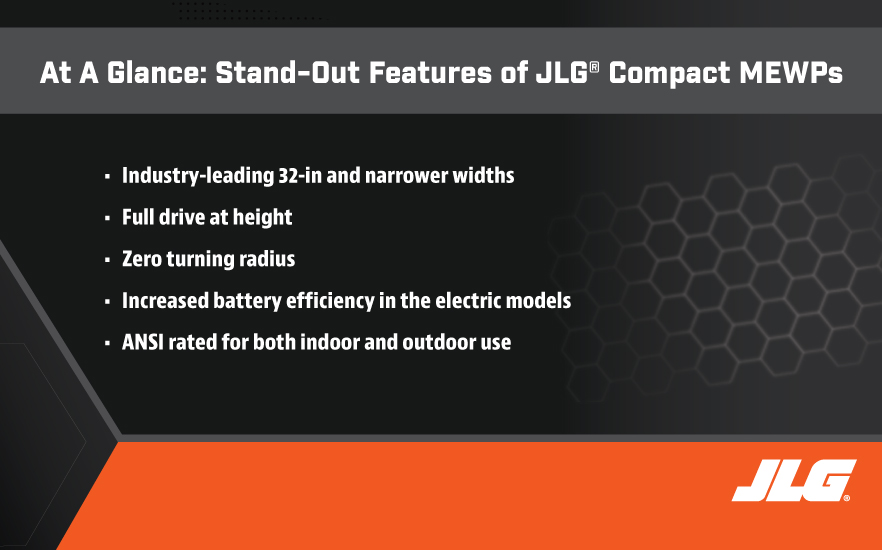

Other stand-out features include industry-leading 32-in widths, full drive at height, zero turning radius, increased battery efficiency in the electric models and ANSI rated for both indoor and outdoor use.

What are JLG’s most recently launched or updated compact lifts, and what features make it stand out from the competition?

In this category of machine, JLG’s latest models, the ES1330L and ES1530L, offer an expanded electric scissor offering on the compact end of the spectrum where there is an increased demand for smaller, lightweight models. These machines are designed for indoor work on sensitive flooring, such as data centers, while also being rated for work in outdoor applications, which means they can work in more places than competitive models. And, their compact footprints feature an industry-exclusive zero inside turning radius for work in tight spaces, enabling operators to maneuver around job sites more efficiently.

These models share parts commonality with larger JLG scissor lift models to lower the total cost of ownership and are available with JLG’s exclusive CleanGuard® Leak Containment System and Advanced Battery Monitoring System.

What are the key product development trends in compact MEWPs, and why?

There is more demand right now for environmentally friendly equipment for this size of the machine, requiring fewer scheduled services and less dependency on hydraulic oils while offering zero emissions and a quieter work area. This is driving product development for more advanced electrified solutions, including offering additional all-electric models and utilizing lithium-ion battery technology.

Customers also expect newer compact scissor lift models to feature the same technologies that enhance the operation and operator experience as their larger counterparts offer. For example, JLG ES1330L and 1530L scissor lift models feature variable tilt functionality, enabling a larger work envelope when operating on slight slopes.

We also see a growing use of these machines on unimproved surfaces (established demand in Japan and an increasing trend in North America), opening the possibility of adding models with flexible tracked undercarriages in the future.

JLG manufactures a full range of compact MEWPs. Find specs for all the different model options here.

Do you want to stay up-to-date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from #DirectAccess with newly posted content so you never miss important information.