JLG Industries, Inc.

JLG Industries, Inc.

World-leading access equipment manufacturer

____

McConnellsburg, PA

Regardless of the size, type and age of the equipment, mobile elevating work platforms (MEWPs) like scissor lifts benefit from routine care and maintenance to keep them operating at peak performance. One of the most important preventive maintenance tasks for fleet owners and owner operators to keep up with is the annual machine inspection (AMI).

According to the current ANSI/CSA industry standards, which went into effect in June 2020, an AMI is a maintenance procedure that must be conducted once a year (no later than 13 months from the previous date) on every scissor lift in an equipment fleet — regardless of brand, make or model. This task gives equipment owners and fleet managers the opportunity to verify that their scissor lifts, and all the machines’ components, are in good operating condition — which is crucial to the safe use of these types of aerial lifts.

Preparing for the AMI

The standards state that an AMI is to be performed by a mechanic qualified on the specific make and model of scissor lift. For best results, JLG further recommends that that person be a Factory Trained Service Technician, which the company recognizes as a person who has successfully completed JLG Service Training for the specific JLG product model.

Before beginning any inspection on a JLG® scissor lift, qualified personnel must first with read and understand the machine’s Operations & Safety Manual because, when conducting an annual inspection, it is important to follow the manufacturer’s recommendations and specific guidance on inspecting procedures and criteria. Also, JLG encourages mechanics refer to the appropriate Service & Maintenance manual for the specific model for additional details about the required machine inspections and maintenance. Manuals for JLG scissor lifts can be accessed here or in the technical publications section on Online Express, JLG’s online parts ordering system and resource center.

Starting an AMI

To begin an annual machine inspection, mechanics need to download the AMI form for JLG scissor lifts, available here, and prepare one form for each machine in the fleet, including the unit’s serial number, model details, hour meter reading, previous inspection date and the product owners’ name and address.

During the inspection, check each item listed on the form, indicating with a Y (= Yes) if it passes, N (= No) if it fails or C (= Corrected) if a discrepancy has been found and fixed. NA (= Not Applicable) can be marked if the item is not relevant to the specific machine.

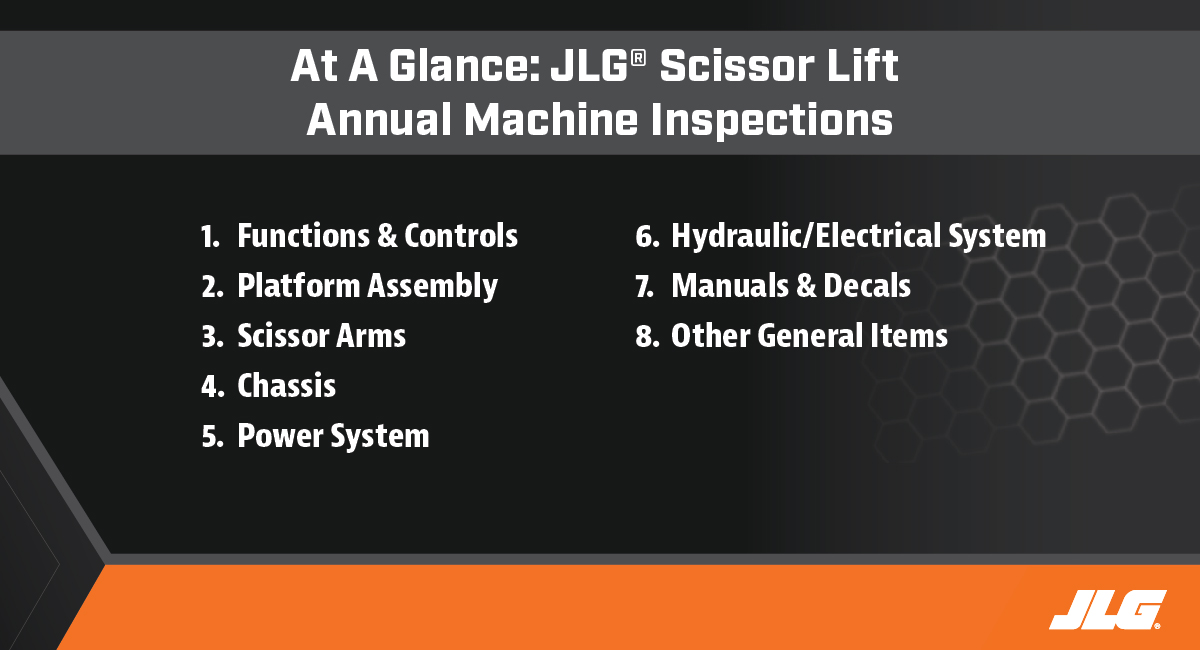

For JLG scissor lifts, there are eight areas of the machine that must be inspected during this annual procedure:

- Functions & Controls

- Platform Assembly

- Scissor Arms

- Chassis

- Power System

- Hydraulic/Electrical System

- Manuals & Decals

- General Items

Here’s a little bit more information on what qualified personnel will need to check on JLG scissor lifts in each of these eight areas during the AMI…

#1: Functions & Controls

- All joystick/toggle controls return to “off” or neutral position when released

- Detents properly lock controls in place. The condition of the control enclosures and protective boots/guards are checked

- Emergency stop switches at the ground and platform control stations arrest all platform movements

- Lift, drive and speed cut-outs operate properly

- The manual descent/auxiliary power system operates properly

- The function enable system operates properly, disabling functions within three seconds

- Brakes operate properly

#2: Platform Assembly

- Platform is installed and secure

- Midrail chain or gate are installed and latches properly

- Extend deck is properly installed and functions properly, locking at full extension and retraction

- Platform guardrails and floor are in place, secure and undamaged

- Platform roll pins and fold-down rails are installed properly. There are no loose or missing parts

#3: Scissor Arms

- Scissor arms are free of damage, cracks and distortion

- Safety prop is installed and operational

- All nuts, bolts, shafts, shields, bearings and locking devices are inspected for proper installation, tightness, excessive wear, cracks or distortion

- Cylinder pins, bearings and attaching hardware are secure and undamaged, as well as not showing signs of excessive wear

- Arm pins, bearings and attaching hardware are secure, undamaged and show no signs of excessive wear

- Arm pads and sliding blocks are secure and undamaged, with no excessive wear

#4: Chassis

- Wheel rim nuts are torqued properly

- Proper tires are installed

- Tires are free of gouges and do not show signs of excessive wear, including no chords showing. And, the tire bead is properly seated around the rim. If the tires are pneumatic, they are properly inflated

- Oscillating axle and lockout cylinders operate properly

- Steer, drive and axle components are secure and undamaged

- Leveling jacks or stabilizers operate properly

- The hydraulic tray and battery/engine compartment covers open and latch properly

- The Pothole Protection system deploys and retracts properly

- Static strap is in place

#5: Power System

- Engine idle, throttle and RPM is set properly

- Correct batteries are installed

- Battery fluid levels are correct

- Battery charger scrolls through diagnostics when plugged in

- Batteries accept charge

- Air and fuel filters are clean

- Coolant and fuel levels are correct

- Fuel cap is tight, and the vent is open

- Exhaust system is free of leaks (gas/diesel units only)

#6: Hydraulic/Electrical System

- All cylinders are free of damage, and there is no evidence of leaks

- All areas around the hydraulic components (pumps, oil lines, reservoir) are free of oil, with no evidence off leaks

- Hydraulic filter is clean

- Hydraulic levels in tank and the torque hubs are correct

- Hydraulic tank cap is tight and vent is open

- All hydraulic fitting and lines are secure, and they are free of damage, chafing and leaks

- All electrical connections are tight, with no corrosion or abrasions

- Instruments, switches, gauges, horns and lights operate properly

- Switches and controls are sealed properly

- All hydraulic pressures are properly adjusted

#7: Manuals & Decals

- The manual storage box contains the ANSI/SIA Manual of Responsibilities (MOR), the Operations and Safety Manual and the AEM Handbook

- Capacity decals are in place, secure and legible, at both the platform and ground control stations

- All safety and instructional decals are installed, secure and legible

#8: General Items

- Lift is free of unauthorized modifications or additions

- Paint and overall appearance are in good condition

- Applicable Safety Bulletins are completed

- General structural condition, including all welds, has been inspected

- Greasing and lubrication has been done per guidance in the Service & Maintenance Manual

- The machine has been driven and operated to test all machine functions

- If ownership has changed since the last inspection, the Owner Update form has been completed and returned to JLG

Completing an AMI

Any discrepancies found during the AMI must be noted and described on the AMI form. Mechanics are also encouraged to include any other general comments on the condition of the machine. Including these details ensures that any and all discrepancies have been brought to the attention of equipment owners, fleet managers and other users.

If any items found to be not acceptable, the scissor lift must be immediately removed from service (tag out), and any repairs to defective or damaged components should be made as soon as possible by a qualified person. To promote the importance of job site safety, no one should operate, or otherwise use, the scissor lift until all discrepancies have been corrected.

Helping keep owners, fleet managers and operators informed on best practices for maintaining MEWPs, guidelines for annual machine inspections on JLG scissor lifts are outlined in both the appropriate JLG Operations & Safety Manual and Service & Maintenance Manual, as well as in AMI forms available here.

Do you want to stay up-to-date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from #DirectAccess with newly posted content so you never miss important information.