JLG Industries, Inc.

JLG Industries, Inc.

World-leading access equipment manufacturer

____

McConnellsburg, PA

Because mobile elevating work platforms (MEWPs) and telehandlers are used in a wide range of construction applications, everything from new building starts to renovation and restoration projects, these machines will work on ground conditions that can vary greatly from site to site — from undeveloped terrain one day to finished floors the next.

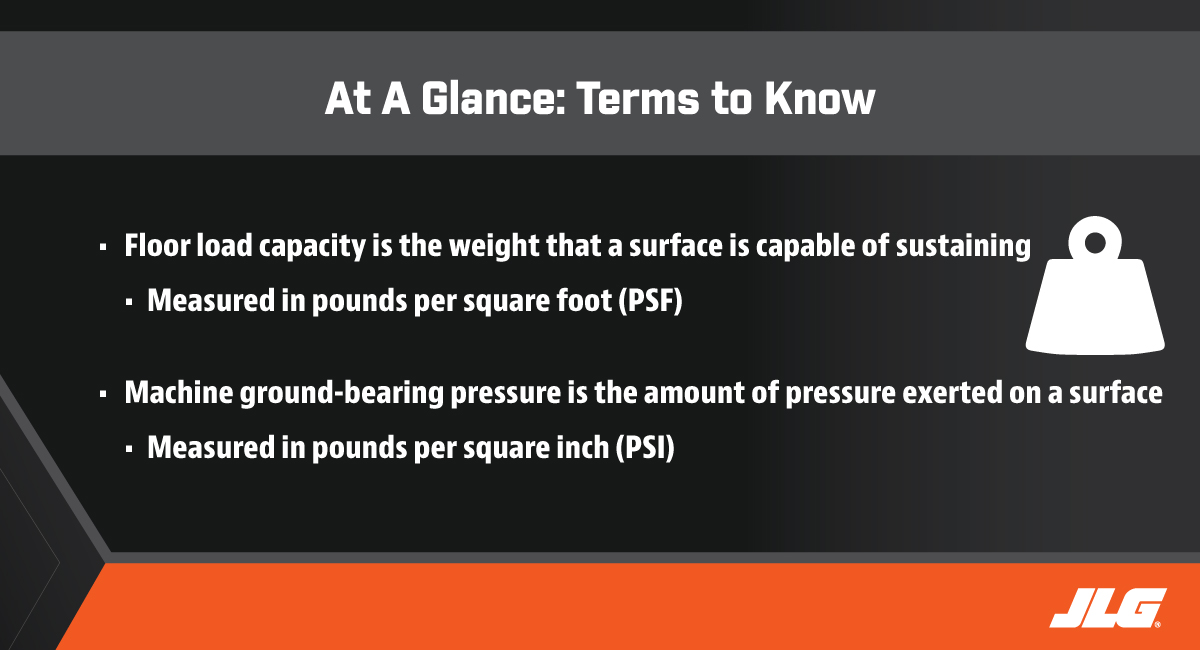

To best prepare on-site crews for working on different types of surfaces, project planners need to pay attention to two specs: 1) Floor load capacity and 2) machine ground bearing pressure.

Floor loading capacity is measured in pounds per square foot (PSF). Machine ground bearing pressure is measured in pounds per square inch (PSI). There is not a direct conversion between floor load capacity (floor loading) and ground bearing pressure (pressure bearing).

Because these specs seem similar, it is not uncommon for crews to use the two terms interchangeably, but they are not the same. To be successful on any given project, it’s important to know the differences between the terms (and the specs) and why each is so important…

What is Floor loading capacity?

Floor load (also referred to as floor pressure) is the total weight capacity that a floor can sustain in a given area.

Why is floor load important? Because any JLG® MEWP or telehandler used on a job site is only as strong as the ground or surface the machine is working on. For example, floors are engineered and constructed to only handle a certain amount of floor loading. If this load is exceeded, there is an increased risk of compromising the structure and damaging the floor — which comes with very costly consequences. So, before work begins, it is critical to know if the ground or surface can support a machine’s weight, or floor load, during work and travel.

Also, it’s important to know that the floor’s load capacity may change over time, depending on the materials its constructed with, its age and the environment. For example, if a JLG machine is working on a freshly poured concrete slab, that slab will have a lower floor load capacity than a fully cured slab. Or, if a JLG machine is working on fully compacted earth, like a site that’s been heavily graded for a new road or building construction, that surface will have a higher capacity than softer, looser dirt conditions, like what would be found in someone’s yard.

Safety first with floor loading

Before operating, always check the allowable capacity of the surfaces, including floors, bridges, etc. Also, figure out if the machine could potentially damage the surface during operation, such as leaving ruts in the soil or scuffs on the concrete. Whenever possible, operators should consult with a structural engineer or other qualified people to know as much as possible about job site surfaces where work will be done.

Where can you find information on a floor’s load capacity?

Project managers should check with the project's structural and/or architectural engineer to find the floor loading capacity specification. Either of these professionals will be able to assess the project site and make the necessary calculations needed to determine this critically important measurement.

What is Ground pressure bearing?

Ground bearing pressure is the amount of pressure exerted on the ground by a JLG machine’s tires, tracks and/or outriggers (exact specifications for every JLG MEWP or telehandler can be found in a machine’s Operations & Safety manual).

Why is it important?

Because as a JLG machine is working, it is not just the machine’s weight that tests the floor’s strength but also the amount of stress applied to the ground or surface by the machine during work and travel. Too much stress on a floor may start with small, seemingly harmless cracks, but over time, it can contribute to failure, leading to collapses or cave-ins — which can lead to hazardous situations for people and property.

You must understand that the JLG MEWP’s or telehandler’s contact area and orientation will significantly influence this specification. For example, increasing the size of the contact area of the machine on the ground (i.e., its footprint), to its weight, will decrease the ground pressure. Lower ground pressures are recommended for working in fragile ecosystems, such as extremely soft turf, like sugar sand, or on extremely delicate flooring, like ceramic tile. Decreasing the ground pressure also increases the machine’s flotation, which allows it to travel better over soft terrain.

To be even more precise in knowing how much strain a JLG MEWP or telehandler is exerting on the floor, it is important to also become familiar with some other machine terminology, in addition to the ground-bearing pressure. In addition to the lingo you need to know, here are some additional terms to understand:

- Maximum Machine Weight: The machine’s weight in its heaviest configuration, excluding accessories.

- Maximum Platform Capacity (rated load): The maximum allowable weight in the platform, excluding accessories.

- Maximum Load: The maximum load supported while the machine is in its working configuration, supporting its rated load.

- Maximum Ground Bearing Pressure: The maximum pressure exerted while the machine is in its working configuration and supporting its rated load.

Safety first with pressure bearing

For safe operation, JLG MEWPs should be positioned on a smooth, firm surface within the limits of the maximum operating slope before elevating the machine’s platform or driving with the platform in an elevated position. Operators should never exceed the machine’s allowable side slope or grade, especially while driving. The machine’s platform should not be elevated, either while the machine is stationary or being driven while working on or near a sloping, uneven or soft surface. When working around potential ground-level obstructions, like holes, bumps, drop-offs or debris, position the machine’s chassis at least 2-ft (0.6 m) from the hazard.

Want to learn more? For more information, click here.

Where can you find these specs for JLG MEWPs and telehandlers?

Project managers should reference JLG-approved equipment spec sheets for machine details, including ground bearing pressure, weight, rated load capacity and maximum load. JLG MEWP and telehandler Operations & Safety manuals can be found online in the technical publications section on Online Express or by clicking here.

The importance of understanding floor loading

If knowing the floor’s load capacity and the machine’s ground bearing pressure is extremely important to successfully plan a project, then conducting a workplace inspection before project start-up is critically important to successfully execute a project.

Precautions to avoid all hazards in the work area must be taken before and during the operation of any JLG machine, including anomalies in a floor that aren’t of the same capacity as the typical floor such as access panels, masked cavities under a surface, tunnels under sidewalks, septic tanks in yards and so on. Workplace inspections can help identify these hazards by:

- Checking the operating surfaces for holes, bumps, drop-offs, obstructions, debris, concealed holes and other potential hazards.

- Making sure that the ground conditions are adequate to support the maximum tire load (indicated on the tire load decals on the machine’s chassis, adjacent to each wheel). It is important to not travel on unsupported surfaces.

- Examining the work area for hazardous locations. The machine should not be operated in hazardous environments unless approved by JLG for that purpose.

Want to learn more? For more information, click here.

JLG provides information on everything safety-related, from inspections and manuals to how-tos and manlift safety videos to support its equipment owners and users. To access essential aerial lift safety, product and training information relating to JLG equipment, click here.

Do you want to stay up to date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from #DirectAccess with newly posted content, so you never miss important information.