JLG receives many inquiries each year regarding the use of fall protection equipment for its mobile elevating work platforms (MEWPs), formerly known as aerial work platforms (AWPs). JLG requires equipment owners, users, operators, lessors and lessees to be in compliance with all applicable standards and regulations (including employer, local, state and national) pertaining to the utilization of mobile elevating work platforms.

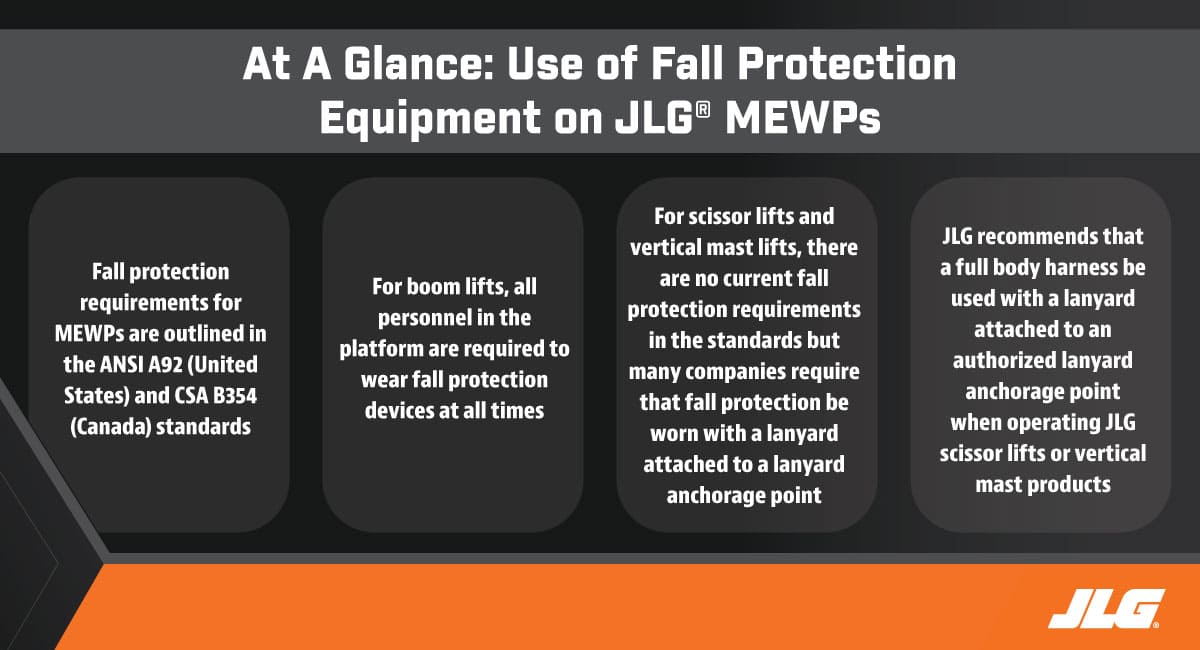

Therefore, fleet owners and machine operators must understand the fall protection requirements under the ANSI A92 (United States) and CSA B354 (Canada) standards. Below you’ll find guidance on fall protection for boom lifts, scissor lift fall protection and information on lanyard anchorage points.

Fall protection for boom lifts

For fall protection on boom lifts, all JLG® models are presently manufactured with lanyard anchorage points. The ANSI Standard for Boom-Supported Elevating Work Platforms (A92.5) and the Canadian Standard for Boom-Supported Elevating Work Platforms (CSA B354.4) require that all personnel in the platform wear fall protection devices at all times.

In the United States, the OSHA regulation for aerial lifts (CFR 1926.453 (b)(2)(v)) requires occupants of the platform to wear a body belt with a lanyard attached to the boom or basket when working from an aerial work platform. As of January 1, 1998, OSHA’s fall protection rule requires the use of a full body boom lift harness for fall arrest in place of a body belt when working from an aerial work platform. The full body harness shall be attached, via a lanyard, to a lanyard anchorage point.

Vertical Mast & Scissor Lifts Fall Protection Equipment

There are no current requirements by ANSI/SIA, CSA or OSHA requiring personnel to wear scissor lift fall protection (machines covered under the ANSI A92.6 and A92.3 and CSA standards B354.2 and B354.1).

Although not required by either ANSI, CSA or OSHA, JLG recommends scissor lift fall protection and vertical mast lift fall protection via a full body harness with a lanyard attached to an authorized lanyard anchorage point when operating JLG scissor lifts or vertical mast products that do not have a 30-in. (76 cm) maximum lanyard length limit.

Machines with a 30-in. (76 cm) maximum lanyard length limit have a decal located next to the lanyard anchorage point indicating this maximum length. A fall restraint system must be utilized where fall protection equipment is to be used on machines with a 30-in. (76 cm) maximum lanyard length limit. Use of fall arrest systems is not authorized.

For certain JLG vertical mast products designed with the capability to open (retract) or remove the guardrail, JLG requires that appropriate fall protection equipment be used with a lanyard attached to an authorized lanyard anchorage point when the guardrail is not positioned entirely around the perimeter of the platform.

JLG presently manufactures new scissor and vertical mast lifts with lanyard anchorage points as standard equipment for mast and scissor lift fall protection. For certain older models of JLG scissor and vertical mast lifts, not originally equipped with lanyard anchorage points, an authorized JLG distributor can install lanyard anchorage points per JLG specifications for the respective JLG product. These authorized lanyard anchorage points, as installed by JLG or properly installed by an authorized JLG distributor, are considered a means of fall arrest for a fall protection system.

On certain older model JLG scissor lifts that are not equipped with authorized lanyard anchorage points for scissor lift fall protection, the user may attach to the mid-rail section of the main platform rail to provide adequate scissor lift fall protection.

Lanyard anchorage points

Lanyard anchorage points, as originally equipped or authorized by JLG for installation on JLG products, are designed and tested by JLG. These authorized lanyard anchorage points meet or exceed the 5,000-lb (2273 kg) static pull test requirements set forth in the OSHA Standard 1926.502, section (d) (15) and lanyard anchorage point testing criteria as required in the applicable CSA B354 standard. Each authorized lanyard anchorage point is designed specifically to be utilized by one (1) person only. There must be an authorized lanyard anchorage point for each additional person(s) in the platform.

When operated with manufacturer’s operating instructions and recommendations, JLG products will remain stable should a person fall out of the platform while properly wearing an approved fall protection device (where the fall is limited to 6- ft or less) attached to a designated anchorage point. For JLG products designated for use with a 30-in. (76 cm) maximum lanyard length, a fall restraint system would prevent a person from falling out of the platform.

Your safety is very important to JLG. To better support you and your customers, JLG provides information on everything safety-related, from fitting a boom lift harness correctly, inspections and manuals to how-tos and manlift safety videos and fall protection equipment recommendations. To access essential aerial lift safety, product and training information relating to JLG equipment, visit parts-services.

Do you want to stay up to date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.