John Boehme

John Boehme

Senior Product Manager - Telehandlers

____

JLG Industries

Telehandlers rated at a lift height of 44 ft and above are classified as high-reach models. It’s important to know that these telehandlers are different from high-capacity models, which are known for their maximum lift capacities and are well-suited for pick-and-carry applications.

High-reach telehandlers, like the JLG® 1075 model, are pick-and-place machines that can deliver job site materials to higher heights. like upper floors of buildings or even on top of the buildings. Such as getting drywall, windows, lumber or flooring up to the 6th, 7th or 8th stories. Or, bringing up roofing materials onto rooftops, setting HVAC systems or roof trusses into place or even moving and storing fabricated swimming pools.

Traditionally, cranes are used for this type of work. That’s because, historically, these machines were the only equipment that could get materials up higher than the 4th or 5th story of a building.

But with today’s high-reach models, like the 1075 and its maximum lifting capacity of 10,000 lbs, operators can now do that kind of lifting with telehandlers.

Increasing the lift height of telehandlers by 25 percent or more reduces operation time and the need for larger, more costly equipment.

It’s not just the 1075’s high-lifting capabilities, though, that makes it a good option to get loads to height. Here are four more advantages this machine offers…

- When job site space restrictions limit the use of other types of equipment, JLG’s 1075 gives operators maneuverability on job sites. Weighing 43,000 lbs and designed with a shorter wheelbase — under 25 ft, it can get into tight access areas. And, having a 13-ft 4-in outside turning radius, 2-3 ft less than comparable telehandler models, it can get into, and out of, confined work areas. Last, but not least, because it’s a rough-terrain machine, it can work in and around the mud and muck on undeveloped job sites. Also, because it weighs less than 45,000 lbs, it can be transported from site to site on a standard tractor-trailer, no special permits needed.

- This type of telehandler can place materials at height with the same as, or even more, precision than other types of machines, especially when equipped with remote boom control. This add-on feature allows the operator to work outside the cab for better visibility of the load, opening up opportunities for owners/operators to choose a smaller, less expensive machine versus a crane to get the work done.

- The 1075 can also be used to take materials, like scrap or trash, down and hauled away from the work area. For example, on renovation or demolition projects, anything that is torn out needs to be removed from the building. Think of the JLG 1075 as an 8-story elevator, when equipped with a bucket attachment, operators can fill up its bucket with construction debris, bring the load down, go dump and come back for more. It offers an efficient way to clean up job sites without bringing in additional machinery.

- Another driver for telehandlers with longer booms like the 1075 is their added reach. High-reach telehandlers can not only lift higher, but they also can extend further to get materials into the interior of buildings where it is needed. This capability enables the 1075 to achieve precision placement further onto or into a building. For example, with 60-ft of forward reach, the 1075 equipped with a a sheet material handler attachment (JLG’s solution for picking and placing sheetrock, drywall, plywood, greenboard, and other sheet materials at the job site) can unload material from a truck, shuttle it to the work area and then deliver it inside the structure or at height in the ideal position where workers are ready to unload it and get to work. This reduces material re-handling and manual labor in work zones, which can drive significant productivity gains on project sites.

Placing loads adjacent to work sites eliminates the need for secondary handling, increasing efficiencies.

We developed the high-reaching 1075 so that our customers could improve their productivity and reduce the need for material re-handling at height.

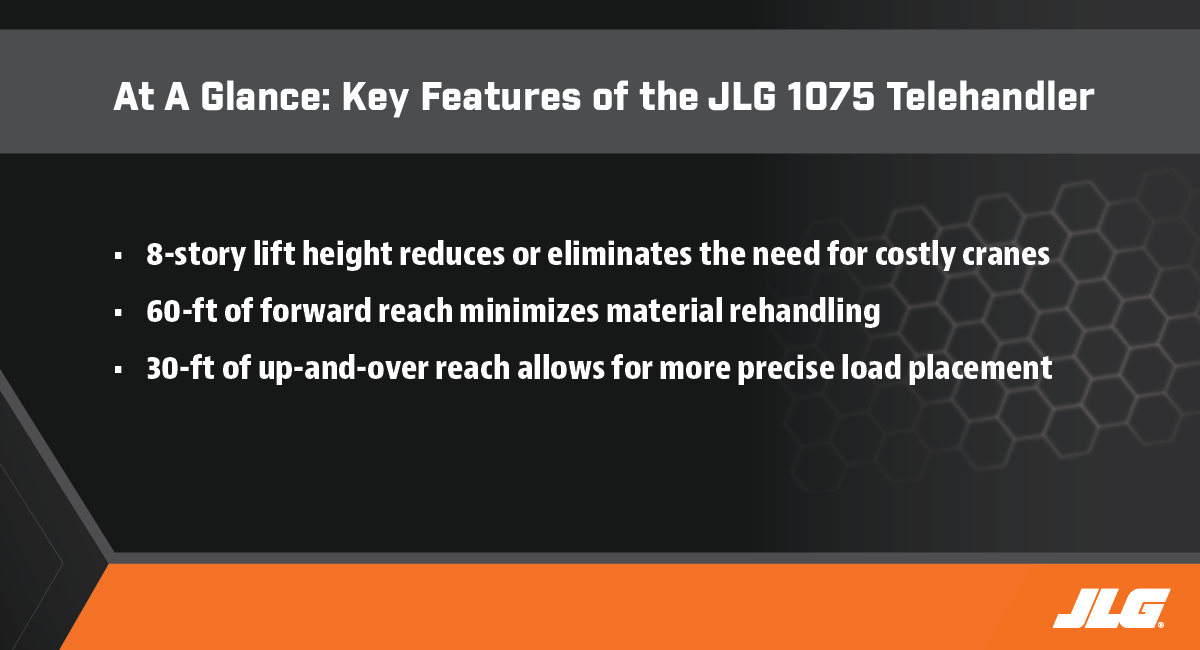

Its 75-ft boom can lift up to eight stories — a full two stories more than comparable, competitive models — and, its 60-ft of forward reach effectively doubles the reach of a telehandler with a 55-ft boom.

And with 30 ft of up-and-over reach, this model allows operators to more precisely place loads in work zones that can be difficult to maneuver around at height, like over roof edges or when access is limited to one side of the structure.

To learn more about how JLG’s 1075 telehandler minimizes material rehandling and reduces the need for costly cranes with its 8-story lift height and enhanced reach, click here.

Do you want to stay up-to-date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from #DirectAccess with newly posted content so you never miss important information.