JLG Industries, Inc.

JLG Industries, Inc.

World-leading access equipment manufacturer

____

McConnellsburg, PA

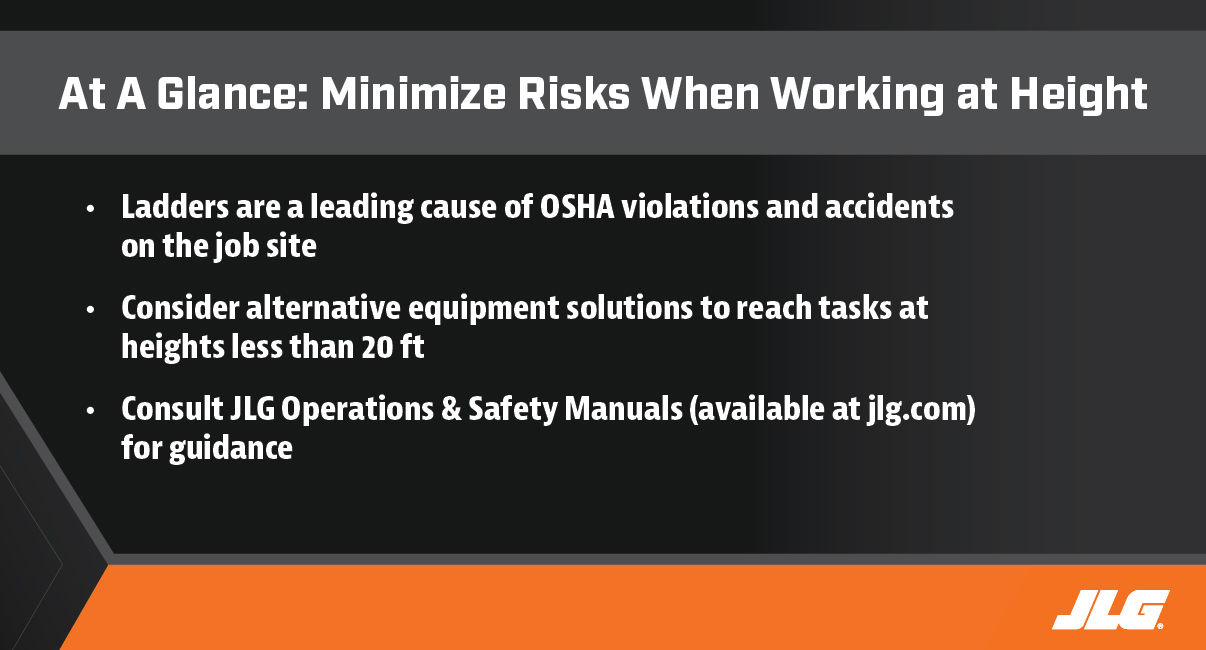

One of the most recognizable tools on the job site — and one of the most dangerous — is the ladder. They have been around a long time, and unfortunately, they are at the center of many accidents. In fact, more than 80 percent of fall injuries by construction workers that resulted in a visit to the emergency room involved the ladder. And, ladders can lead to other hazards too, including fatigue and strain.

When accessing lower heights, let’s talk about a better alternative: Equipment that offers protection and minimizes the risks associated with work at heights less than 20 ft.

But, what are those options?

One solution is low-level access lifts. Not only do these machines reduce the fatigue and strain from repetitively going up and down the ladder, but they also offer key safety features to help people work safer and with more confidence compared to ladders.

For starters, as soon as operator step into the platform, they are immediately protected by guardrails.

Plus, operators have the flexibility to work at the correct height. How many times do we see workers on ladders stretching above their heads to reach the work because they aren’t quite high enough? This puts these workers at risk for falling, as well as overextension injuries.

And with low-level lifts, there's no climbing so less fatigue — just get in and go.

Let's take a closer look at these six key safety features that JLG has incorporated into its low-level access product:

- All JLG low-level access lifts have platform rails, which keep the platform fully enclosed so the operator is more secure.

- Because lanyard use is required, all platforms on JLG machines have lanyard anchorage points.

- Unlike ladders that always require three points of contact, JLG low-level access lifts give the operator a 360-degree range of motion with both hands, which allows a more ergonomic working position with less strain on backs and necks.

- These machines’ platforms have plenty of room for tools and supplies, which eliminates repeated trips up and down for materials, reducing time and fatigue.

- There are features built in to both the powered and non-powered units that allow operators to safely elevate and lower the machines. And these low-level access lifts also have a feature that lets the platform be raised or lowered from the ground. This feature is useful in rare cases when an operator is incapacitated and unable to lower the machine.

- Automatic locking wheels ensure that, when a platform is raised, the machine remains stable while an operator is at work.

As you can see, JLG developed its product line to improve worker safety with a productive equipment solution for work at heights less than 20-ft. For more details on how these features can help you work safer and with more confidence compared to ladders, check out this JLG® Safety Check video. For more safety tips from JLG, click here.

Did you know JLG Operations & Safety Manuals have all of the essential precautions for your JLG machine outlined? To get guidelines for workplace and machine inspection, as well as learn about dangers and warnings, from trip and fall risks to tipping hazards, search JLG manuals here.

Do you want to stay up-to-date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from #DirectAccess with newly posted content so you never miss important information.