Construction projects across many markets and segments are on the rise, which drives greater demand for telehandlers to support heavy lifting and placing. Telehandlers are generally one of the first machines on a job site, and one of the last to leave.

The higher capacities of high-capacity telehandler models make the particularly well-suited for use on wind farms, and in the industrial construction, mine and quarry, power plant, logging and energy (oil and gas) industries. High-capacity telehandlers help users save time, money and labor on the job site by allowing operators to accomplish multiple tasks with one machine. Their higher lift capacity help minimize the number of trips required to move bulky, heavy materials, while their enhanced versatility allow them to move efficiently across the work site for improved productivity.

With the growing demand for high-capacity models, comes the need to help people understand how they differ from traditional telehandlers. Below are answers to some of the most frequently asked questions we get about high-capacity telehandlers.

What does JLG consider to be a high-capacity model?

The generally accepted telehandler classifications are set by the Association of Equipment Manufacturers (AEM) with input from OEMs for the purpose of market share reporting. The telehandler classifications for North America are based on maximum lift capacity, whereas in Europe they are typically segmented by maximum lift height.

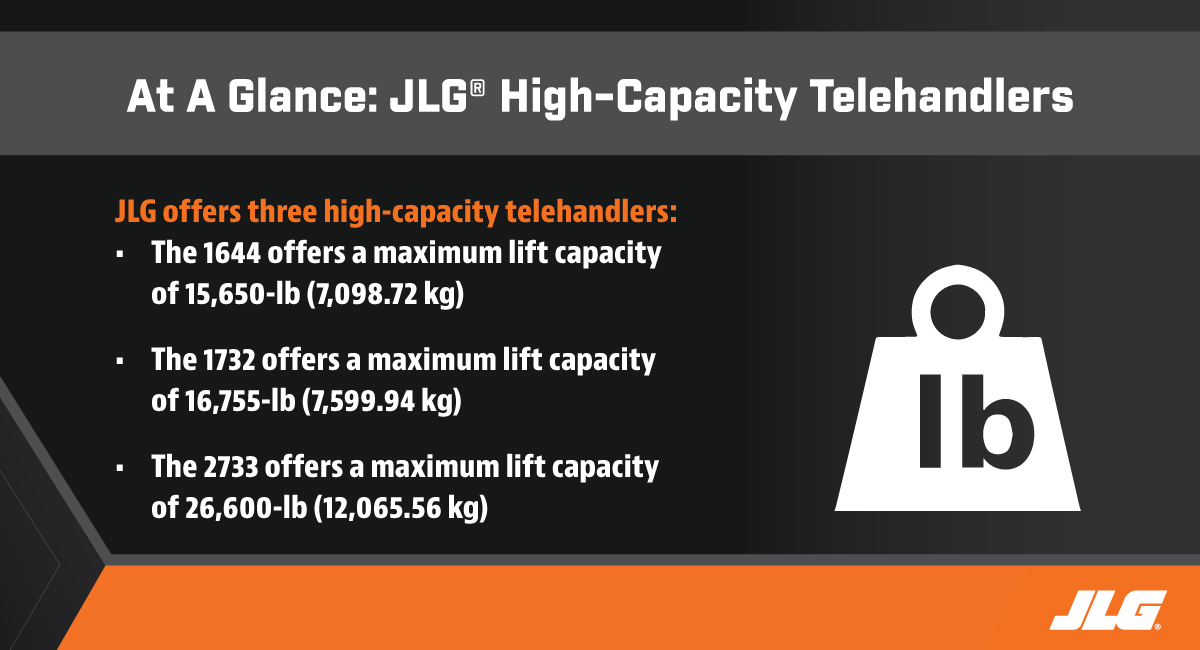

JLG follows the categories defined by AEM. Essentially any machine with a maximum capacity over 13,228-lb would be considered to be in the high-capacity class. Today, JLG offers three high-capacity telehandlers — the 1644, 1732 and 2733 models.

Here’s a quick spec check of these high-capacity telehandlers…

1644

- Maximum Lift Capacity: 15,650-lb / 7098.72 kg

- Maximum Lift Height: 43-ft 7 in / 13.28 m

- Maximum Reach: 31-ft 1-in / 9.47 m

1732

- Maximum Lift Capacity: 16,755-lb / 7599.94 kg

- Maximum Lift Height: 31-ft 8-in / 9.65 m

- Maximum Reach: 18-ft 7-in / 5.66 m

2733

- Maximum Lift Capacity: 26,600-lb / 12065.56 kg

- Maximum Lift Height: 33-ft 1-in / 10.08 m

- Maximum Reach: 17-ft 7-in / 5.36 m

What are key features of JLG high-capacity telehandlers?

The JLG® high-capacity telehandlers are the first telehandlers in North America with optional SmartLoad technology. SmartLoad is an advanced bundle of three integrated technologies that work together to deliver a greater level of operator confidence.

The SmartLoad bundle includes:

- AUTOMATIC ATTACHMENT RECOGNITION: Which recognizes the attachment on the end of the boom and displays the appropriate capacity chart to the operator.

- A LOAD MANAGEMENT INFORMATION SYSTEM (LMIS): Which graphically depicts the location of the load within the capacity chart, indicates whether the load is compliant and prevents the operator from violating the boundaries of the chart.

- And a LOAD STABILITY INDICATOR (LSI): Which works with the LMIS system to limit operation when the load is nearing the maximum capacity indicated on the capacity chart.

Armed with real-time load data this package provides operators with increased confidence while fleet owners avoid the costly repairs that may result from overloading a machine.

Additionally, the JLG high-capacity telehandlers were among the first to include JLG’s precision gravity lowering system and a soft stop boom control that slows boom functions at the end of the cylinder stroke. These models also have a reverse camera and optional reverse sensing feature.

These telehandlers were designed with the operator in mind, boasting spacious cabs with enhanced visibility, two-speed hydrostatic transmission and an optional boom float and ride control feature for enhanced load stability when travelling on uneven terrain.

What other features are offered on JLG high-capacity telehandlers?

JLG’s high-capacity telehandler models feature an integrated tow hitch and are compatible with a wide range of standard and specialty attachments to optimize usability across a multitude of applications. The attachment range includes the following:

- Bale clamp

- Bale cradle

- Dual fork positioning carriage

- Pallet forks

- Side-Shift Carriage with Dual Fork Positioning

- Standard Carriage

- Log Handler

- Pipe Grapple

- Coupler Mounted Hook

- Material Handling Arm

- General Purpose Bucket

- Grapple Bucket

- Light Material Bucket

- Multi-Purpose 4-in-1 Bucket

- Coupler Mounted Winch

- Steel Coil Handler

What is driving demand for high-capacity telehandlers?

A lot of the increased demand for higher-capacity telehandler models has to do with the sheer size and scope of materials to be handled. We’re talking about industrial projects where building materials are much larger. And, there are other applications that, like solar and wind power, as well as energy exploration and extraction and mining, where heavy components need to be moved around the work site, sometimes over fairly long distances. The growth in these heavy-lifting applications has led to the need for more versatile and robust machines, like high-capacity telehandlers.

Today, high-capacity telehandlers are being used to do work which has historically been done by small rough-terrain cranes, excavators and wheel loaders equipped with forks to improve productivity with advantages such as compactness, mobility, maneuverability, speed, lift height and forward reach.

The high-capacity market has been buoyed in recent years by the increased use in energy extraction and refinement, along with wind farm construction growth. As specialty industries continue to grow, so too will the demand for high-capacity telehandlers. In fact, we may even see them replace more traditional machines, like wheel loaders, in certain applications where greater reach is desired.

What customer inputs are influencing the high-capacity telehandler market?

As demand increases, JLG continues to focus on delivering features that improve operator confidence and machine versatility such as a spacious cab, a reverse sensing system and reverse camera.

The market also continues to be focused on return on investment, as defined not only by the initial acquisition cost, but also by the total cost of the product over its lifetime. Rental company owners and owner/operators are paying more attention to the versatility of each piece of equipment, the productivity gains it can provide, and its retained value.

With the importance of ROI, telematics is also experiencing growth. The JLG ClearSky® fleet management telematics solution provides equipment owners and operators access to critical engine and equipment operational data so they can make better decisions on their investment. Data points, including location, engine hours, usage, fuel and battery levels, and maintenance schedules are conveniently available in real-time and accessible from desktop or mobile devices.

What tips can you offer contractors when renting or buying high-capacity telehandlers?

Higher-capacity telehandlers serve both the rental and retail segments of the market. While some end-users enjoy the flexibility that comes with renting a machine when they need it, others may prefer the convenience of owning. What one chooses depends greatly on the application and customer needs.

With so many jobs to be done, it’s important to ask the right questions when selecting a high-capacity telehandler. There are a number of factors that need to be considered including:

- What is the weight of the loads to be placed?

- What heights do those loads need to be lifted to?

- What reach is required?

- What type of material is being moved?

- What surfaces will the machine be operating on?

- How much space is available to operate the machine?

- Is an open or enclosed cab more appropriate for this job?

- Are there any options or accessories that need to be considered, such as lighting?

- What types of attachments are required for the work to be done?

If you are in the market for a high-capacity telehandler, speak to your local rental company or equipment dealer who can help you determine the right model, accessories and attachments for your job.

Interested in learning more about JLG high-capacity telehandlers? Click here.

Do you want to stay up to date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.