Mark Vaughns

Mark Vaughns

Director of Product Safety & Reliability

____

JLG Industries

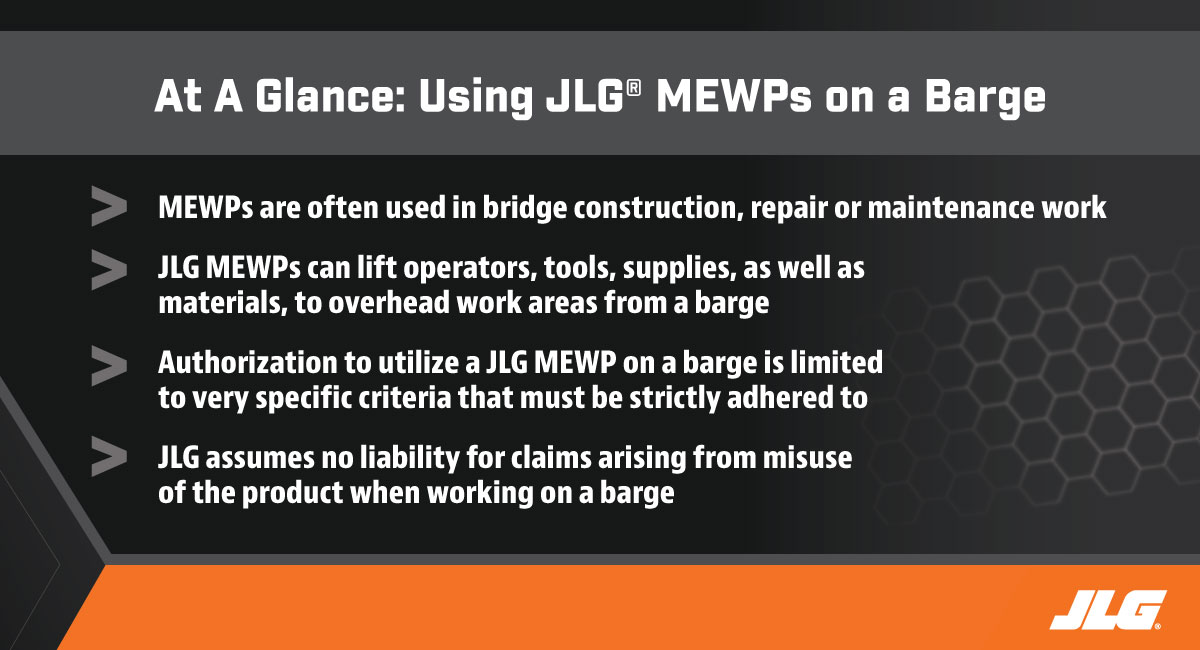

JLG® mobile elevating work platforms (MEWP) are used in a wide variety of applications in and around construction sites, including for bridge construction, repair or maintenance work.

Often, JLG equipment in these applications are used to lift operators, their tools and supplies, as well as materials, to the work area from a barge floating on the water below.

Authorization to utilize a JLG MEWP on a barge is limited to very specific criteria that must be strictly adhered to, including the following:

- The size of the barge shall exceed the footprint of the MEWP in its operating configuration, taking into account extendable axles and outriggers (if applicable).

- The MEWP being used must be current with Annual Machine Inspection requirements, with all noted discrepancies properly corrected. Additionally, ensure that all decals/placards are legible and properly installed (positioned) on the machine and the JLG Operator & Safety manual and other appropriate publications are located within the designated manual storage compartment.

- Operators of the MEWP must be properly trained in its operation. Each operator, before assuming control of the JLG MEWP, must complete the required walk-around inspection and function checks.

- All applicable safety procedures (country, local, employer, manufacturer, etc.) must be strictly followed.

- Except while over water, personnel occupying the platform must wear appropriate fall protection equipment. While working over water, workers shall wear a personal flotation device (PFD).

- The barge surface, as well as the approach or access surfaces to the barge, must be capable of sustaining the weight of the machine. Reference the specifications section of the Operation and Safety Manual for the approximate weight of each MEWP.

- The barge must be of adequate size and capacity to minimize list (side-to-side) and trim (fore-to-aft) movements while the MEWP is being utilized in all operations and loaded up to the rated capacity. The list and trim must not exceed 1 degree at any time during operation of the MEWP.

- All safety precautions, as outlined in the applicable Operation & Safety Manual for the appropriate JLG MEWP, must be adhered to.

- Do not use motion of the barge for final positioning of the MEWP. The barge must only be repositioned with the lift in the stowed position.

- When operating a JLG Group B MEWP (Boom Lift) on a barge, the lift must be secured to the barge via appropriately sized chains/slings etc. Drive functions must be disabled to prevent operation, except for the sole purpose of loading/unloading from the vessel. In addition, the lift must be centered both across the port and starboard directions of the vessel.

- Prior to operation of the lift functions of a JLG Group A MEWP (Scissor or Vertical Mast Lift) on a barge, the lift must be secured to the barge via appropriately sized chains/slings etc. Drive functions must be disabled to prevent operation while the platform is elevated. Barricades must be present to prevent the lift from being driven off the sides of the barge.

The owner(s) and user(s) of the JLG MEWP are responsible for the structural integrity and selection of the barge for this application. More guidance on safety requirements for operating JLG MEWPs is available safety.

Want to stay up to date with industry news and trends similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.