Randy Marzicola

Randy Marzicola

Director, Business Development

____

JLG Industries

As safety continues to be a focus on job sites, companies are turning their attention to low-level access lifts.

In addition to offering a safer alternative to ladders, scaffolding and other forms of access, these versatile machines may also enhance productivity, ergonomics, and even green benefits that are increasingly of interest to building owners, facility managers and machine operators.

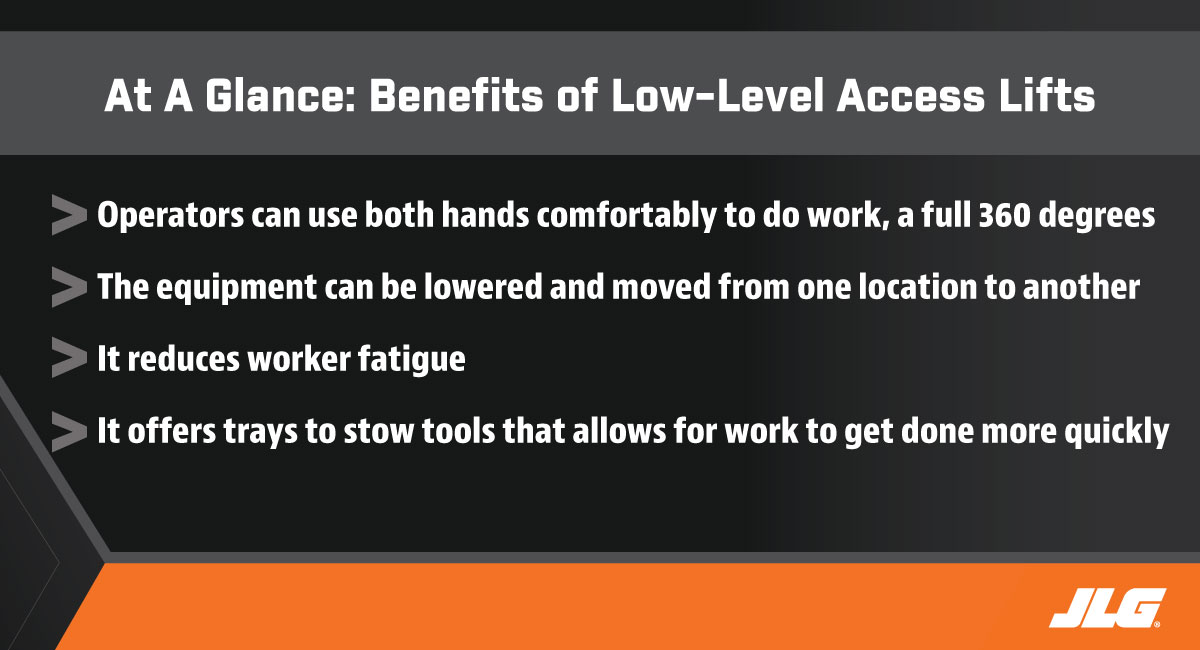

Operators in low-level equipment can use both hands comfortably to do work safely at height, a full 360 degrees. This isn’t the case with ladders, where workers often must use one hand to stabilize themselves at height, leaving only one hand free to perform a task. This equipment also features portability benefits. Low-level access equipment can be lowered and moved from one location to another, making it easy to perform multiple tasks throughout a facility in less time.

The non-powered realm of low-level access lifts includes models that feature a patented stored power lift system that requires no batteries, hydraulics, oil or controls. Because no hydraulics or motors are involved, these eco-friendly lifts are leak-free and operate quietly, making them a preferred piece of equipment for work in schools, hospitals and other institutions.

It’s also important to note that low-level access equipment helps with worker fatigue. With ladders, a worker must climb up and down to get the tools he or she needs. It can be exhausting work and can lead to an increased risk of falls or injuries. However, low-level access equipment offers trays to stow tools that allows for work to get done more quickly.

JLG offers innovative low-level access equipment options to replace ladders, including:

JLG® LiftPod® Personal Portable Lifts

- Standard tool tray holds 33 lb (14.96 kg) of tools and materials to improve productivity by minimizing trips up and down

- Elevate effortlessly using an 18V cordless drill or an optional 40V lithium-ion power pack

- Easy Setup and Portable — Quickly assemble in your work area, then easily wheel it to your next task; can be transported in the back of a van or pickup truck

- Maneuverable- models fit through a standard single or double doorway

JLG® Non-Powered EcoLifts™

- More productivity because there is no need to erect or dismantle scaffolding or climb up and down ladders

- Power free and hydraulic free, drastically reducing the parts and maintenance, which lowers total cost of ownership

- Sturdy base and automatic locking wheels let you work confidently with both hands, resulting in greater productivity

- Patented stored power lift/lower system offers 24/7 use and trouble-free service. Easily raise and lower with the turn of a crank

For more information about the full line of JLG low-level access equipment, click here.

Do you want to stay up to date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.