If you use a new scissor lift or boom lift, it’s going to be different.

The new ANSI A92.20 standards have overhauled the design requirements for a mobile elevated work platform (MEWP) made after June 1, 2020. These design changes are intended to improve the safety of MEWPs, previously known as aerial lifts, aerial work platforms, or AWPs.

New MEWPs will have features that you may not be familiar with, such as platform load sensing and indoor/outdoor ratings due to wind force restrictions.

At first, all you may know is that the MEWP you rented or bought prevents you from working the way you may have in the past.

And that can be frustrating.

Once you understand the benefits of the new features, you’ll realize they are for your good.

However, any type of change — no matter how valuable — can be initially disruptive to existing workflows. New habits need to be formed. Alternative steps need to be taken.

In this article, Rafael Nunez, senior product manager for scissor and vertical lifts at JLG Industries, will help you navigate some of the new MEWP changes so you can quickly and easily get to work.

What is ANSI A92 and how does it affect me?

According to the Scaffold and Access Industry Association (SAIA), which is the organization that oversees the standards’ development, the ANSI A92 standards outline criteria for MEWP manufacturers to follow with the goal of preventing accidents or injuries.

The new A92 suite of standards includes:

- A92.20 design standard

- A92.22 safe use standard

- A92.24 training standard

While this article focuses on machine design, users should know what safe use and training requirements they need to follow in order to be compliant.

These changes, over a decade in the making, now align more closely with existing global standards for MEWPs.

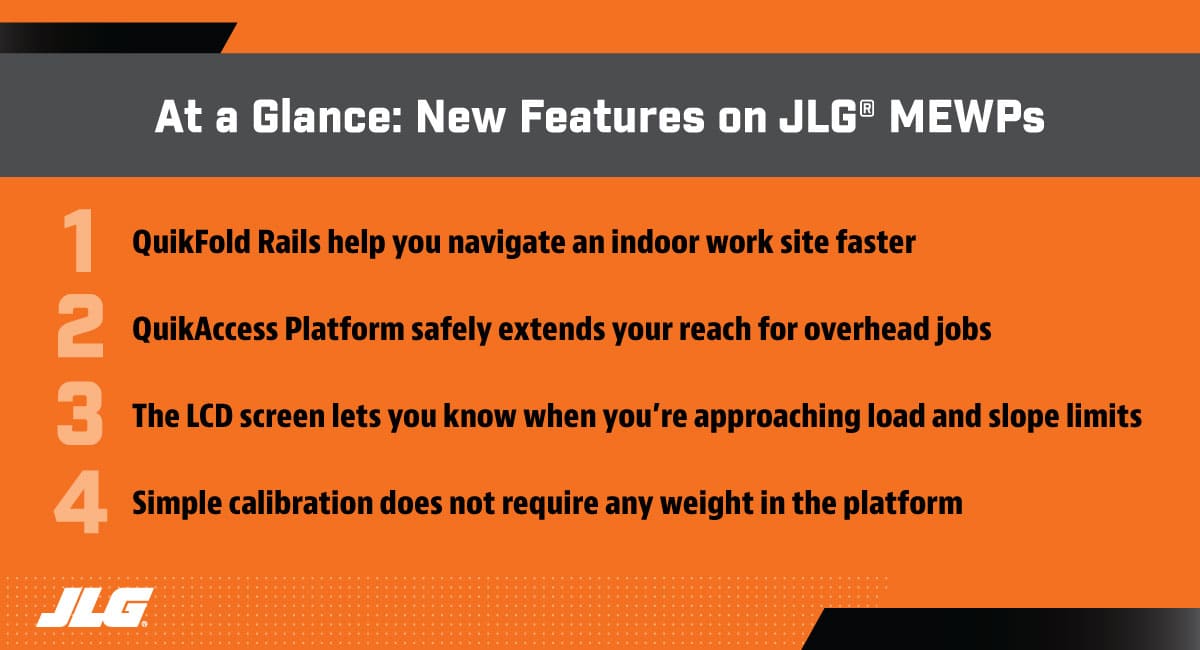

MEWP users will find updates or new technology including:

- Platform load sensing

- Tilt sensing

- Entry gates

- Toe boards

- Tires

- Wind-force ratings

- Railing heights

- Machine markings/decals

- Manual of Responsibilities

But without understanding the needs of operators, these MEWP features can create a new crop of challenges if manufacturers are not careful.

So the redesign process presented an opportunity to find comprehensive solutions for users while improving overall MEWP safety, says JLG President Frank Nerenhausen.

Here’s how some of these challenges are addressed.

Challenge: How can MEWPs get through doors with taller railings?

New requirements for taller rails are making it harder for electric scissor lifts designed for indoor use to fit through standard doorways.

This is resulting in the need for fold-down rails on 19-ft. scissor lifts that previously had fixed rails to reduce their overall height in order to navigate through standard doorways.

Folding down the rails, typically held in place by removable pins, can be time-consuming and disruptive to job site productivity.

Redesigning scissor lifts to be shorter is expensive, and it can impact their performance, Nunez says.

But there’s an alternative.

QuikFold Rails reimagine how the rail system functions.

“You undo those two latches, you go to the rear of the machine, you squeeze, and you fold down,” Nunez says. “It takes three seconds, instead of three minutes, and there's no pins to get lost.”

You undo those two latches, you go to the rear of the machine, you squeeze, and you fold down. It takes three seconds, instead of three minutes, and there's no pins to get lost

QuikFold Rails are available as a standard feature on the AE1932 DaVinci™, ES1932i, and ES1932 scissor lifts, and as an option for the R1932 and R1932i models.

Nunez says another alternative to folding rails are the recently launched lightweight ES1330L and ES1530L lightweight scissor lifts, which fit through a standard doorway with fixed rails. Both models are rated for indoor and outdoor work.

Challenge: How can MEWPs safely access hard-to-reach spots?

You’ve inched your scissor lift as close as you can to where you need to work overhead, but an obstruction is blocking your way. It’s tempting to just take a quick step up on the rails …

STOP! Don’t do it.

“We want the user standing on the platform floor,” Nunez says. “We do not believe that stepping up and above the platform floor meets the ANSI standards.”

So how do you safely get to where you need to go?

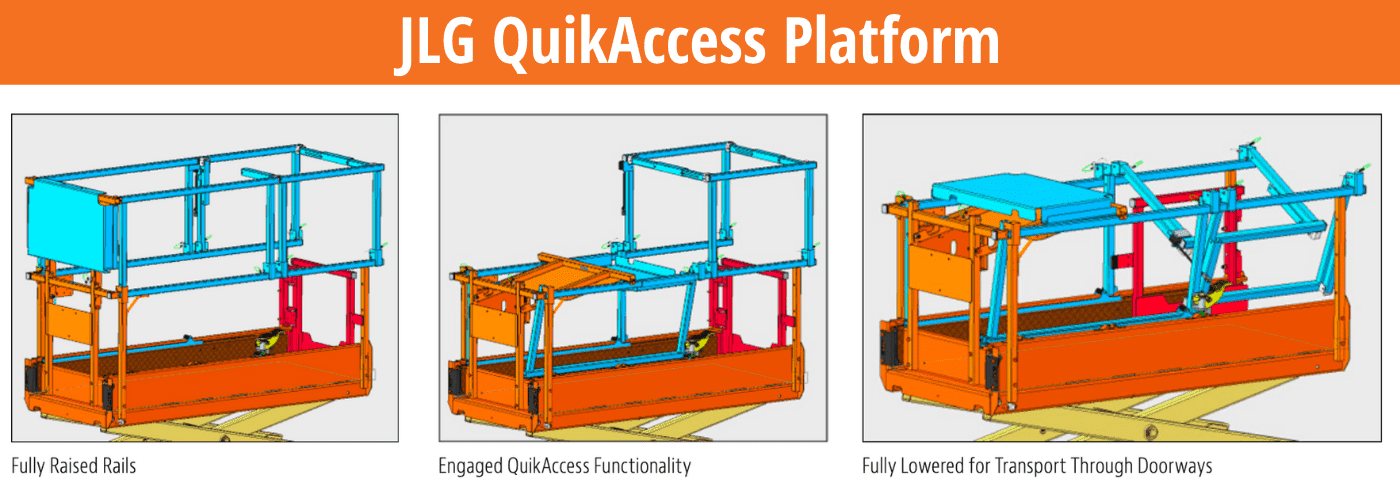

The new QuikAccess Platform is designed to provide 22 in. of extra reach on 19-ft. R and ES models.

It works by folding down most of the rails while keeping the operator narrowly enclosed and protected by full-height rails that meet the ANSI A92 requirements at 43.3 in. This creates an “L” shape of the platform rails that allows the operator to raise the MEWP higher for better overhead access.

As a bonus, the QuikAccess Platform also features a standard tool tray.

Challenge: How do you know if the MEWP is nearing its limits?

Platform load and tilt sensing now prevent MEWPs from operating if limits are exceeded.

But if your MEWP is not working, how can you tell if that’s the problem?

MEWP manufacturers are offering various solutions for this, with JLG introducing an industry-first platform control box with an LCD screen that will show real-time feedback.

The display will provide:

- Side-to-side tilt

- Front-to-back tilt

- Current weight in the platform

- Current height

- Maximum height with current weight and tilt

“Before you start going up, the display is actually going to give you the maximum height you can achieve,” Nunez says. “Not only does JLG offer the widest work envelope of any rough terrain scissor lift, we also communicate to operators before they elevate, which improves job site productivity and eliminates the frustration of not knowing if you will be able to get to where you need.”

That way, you can adjust the amount of material you take in the platform or move the MEWP to a more level location if you need full height.

The new LCD screen will be standard on all JLG electric rough-terrain scissor lifts and select rough-terrain scissor lifts. The 670SJ Self-Leveling Boom also features a similar display for active feedback of operating conditions.

Challenge: How do you calibrate the MEWP’s load sensing?

Platform load sensing systems on new MEWPs will require periodic calibration.

This will need to be done either at six-month intervals or when certain maintenance is performed, such as replacing the elevation sensor, pressure sensors, or ground control module.

There are two ways to perform load calibration, Nunez says.

The most common way is full-load calibration, which means bringing 120% of the machine’s maximum capacity into the platform.

“So if a machine has a capacity of 500 lb., you'd have to bring 600 lb. with you, carry it onto the platform, and calibrate the load-sensing system,” Nunez says.

This can understandably be a laborious process.

The other method JLG offers is simple calibration , which takes as little as five minutes and zero weights.

With simple calibration, a service tech uses an analyzer. This quick method provides between 80% and 95% platform capacity depending on the model, Nunez says.

Once the MEWP returns to the service center, a full calibration can be completed to bring the machine back to full operating capacity.

Seeing the Benefits

The 2016-18 Global MEWP Safety Report by the International Powered Access Federation finds the majority of MEWP accidents resulting in fatalities occur in the U.S.

The new ANSI A92 standards, which are now in effect, aim to reduce incidents and prevent injuries and deaths through machine design, safe use, and training. Users need to familiarize themselves with the standards as part of their overall efforts to safely work at height.

And though the new MEWPs may take some getting used to, users will be ones who will ultimately profit from these changes.

“We’re on a mission to provide a safer way of working at height,” Nunez says. “As we continue to learn from the key stakeholders in our industry, we are introducing additional customer-inspired innovations to further increase productivity and safety while providing a new level of technology on our MEWPs that make them easier to operate.”

Want to stay up to date with industry news and trends similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.