Rick Smith

Rick Smith

Senior Director of Product Training

____

JLG Industries

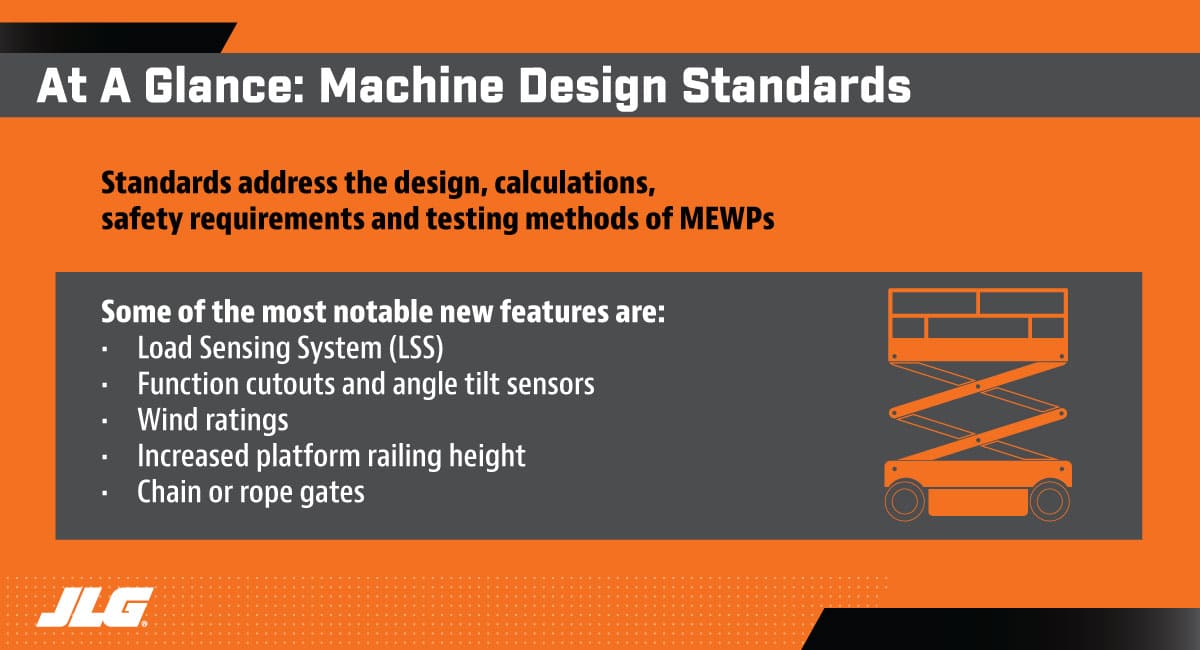

The Machine Design sections in the ANSI and CSA standards — ANSI A92.20 & CSA B354.6, respectively — addresses four key areas of a mobile elevating work platform (MEWP’s) related to the design, calculations, safety requirements and testing methods of these machines.

These sections in the standards act as a guide for manufacturers, like JLG, to be able to build compliant machines.

Under the updated standards, machines have changed. Many new features have been incorporated into MEWPs design that influence the machine’s operation and/or functionality, including:

- Load Sensing Systems (LSS)

- Sustained involuntary operation protection

- Stability with a deflated pneumatic tire

- Stability to include dynamic loading as well as wind loading

- Function cutouts and angle tilt sensors

- Sensing system for broken or slack wire rope in the boom

- Increased platform railing height

- Chain or rope gates

- Removal of the enable switch on the ground control panel

Here is a quick synopsis of what some of these features are and how they can impact machine use…

Load Sensing

Change: Machines are required to actively monitor load and interrupt normal operations/sound an alarm if overloaded.

Takeaway: You need to pay close attention to machine capacity. Jobs are no longer able to be completed with an improperly loaded machine, which means that you need to take the weight of accessories and tools into account when calculating a MEWP’s load.

Tilt Sensing Requirements

Change: Machines that could previously only operate on level surfaces can now be used on slopes but are required to have a tilt sensor alarm and cutout. The system will disable boom and drive functions if the incline surpasses the slope limit.

Takeaway: You need to assess the terrain your machine will need to travel over. Depending on the job site, you may need to reposition your equipment or grade the worksite to complete the job because MEWPs will no longer operate when out of slope.

Wind Force Requirements

Change: To be rated for outdoor use, machines may require reduced platform capacities and/or increased weight for more stability.

Takeaway: You need to check the MEWP you plan to use to see if it’s rated for outdoor use or indoor use only. JLG MEWPs are clearly marked for you.

Entrance Gates

Change: Flexible devices, like chains, are no longer acceptable entrance gates, and toe boards must be on all areas of the platform.

Takeaway: You need to be aware that you will encounter half-height, full-height or saloon-style gates rather than chain entrances on new standards-compliant scissor lifts.

Tires

Change: Most rough terrain equipment is only available with solid and/or foam-filled tires based on new stability testing guidelines.

Takeaway: You need to know that the availability of air-filled tires is limited and take this into account when planning for job sites with soft ground, sand and gravel areas.

Platform Railings

Change: The railing height requirement has been raised for small indoor scissor lifts. This means that to fit through standard doorways, taller, folding rails are needed to replace fixed, non-folding rails on select models.

Takeaway: You may need additional training on the MEWP you plan to use in order to familiarize yourself with how to fold railings to fit through standard doorways.

Machine Markings & Manuals

Change: Operator manuals must include a list of MEWP functions, features, operating characteristics, limitations and devices to be included in familiarization. Each machine must have a dedicated space to mark the date of the last annual inspection.

Takeaway: You should expect that MEWPs should have a current Manuals of Responsibilities on board, and that technicians working on the MEWP you plan to use must be trained on updated marking procedure.

Although manufacturers are impacted the most by these machine design changes, equipment owners and end users should be aware of what the requirements are. Why? Because for equipment owners, such as rental companies and dealers, you need an in-depth understanding for training and servicing purposes.

For end users, changes like load sensing require advanced planning of work at height to make sure that it’s possible to complete with compliant equipment. This means that you will need to carefully consider the application when choosing a MEWP for the job.

You can learn more about the Machine Design specifications in the ANSI A92.20 & CSA B354.6 standards here.

Want to stay up to date with industry news and trends similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.