Your biggest access equipment problems are about to be solved.

Earlier this year, JLG President Frank Nerenhausen spoke to Lift and Access magazine to share how scissor lifts, boom lifts, and telehandlers are all set to go through a dramatic transformation.

By listening to the industry’s unmet needs — and then combining innovation with technology — the answers to users’ most considerable challenges are now within reach.

Because of this, the next life cycle of access equipment is going to look and operate very differently — and we’re not talking about just spec updates.

“We see that there is a need for innovation that goes beyond the incremental,” Nerenhausen said in the interview.

“We need to make … workers more productive and safe on their job sites.”

So what can you expect?

Here are five trends that Nerenhausen said will reinvent how you work at height and move materials in the future, along with specific examples about how those changes can impact you today.

Going Beyond Compliance

Scissor and boom lifts, now known as mobile elevated work platforms or MEWPs, were already getting a makeover, due to the updated design requirements of the new ANSI A92 suite of standards.

In order to achieve compliance, MEWPs produced after June 1, 2020, must include features intended to improve safety, such as platform load sensing, tilt sensing, higher railings, and more.

This provided the opportunity to reexamine MEWP designs as a whole from the operator’s point of view, Nerenhausen said, and introduce additional features to help users easily navigate the required changes to the machines.

Problem: How close am I to reaching load or slope limits?

Solution: Get real-time feedback in the platform.

If you’re not familiar with the ANSI A92 standards, you may not know that the operation of new MEWPs may be prevented if the platforms are overloaded or tilt levels are exceeded.

But how are you going to know if that’s the reason your MEWP is not working right?

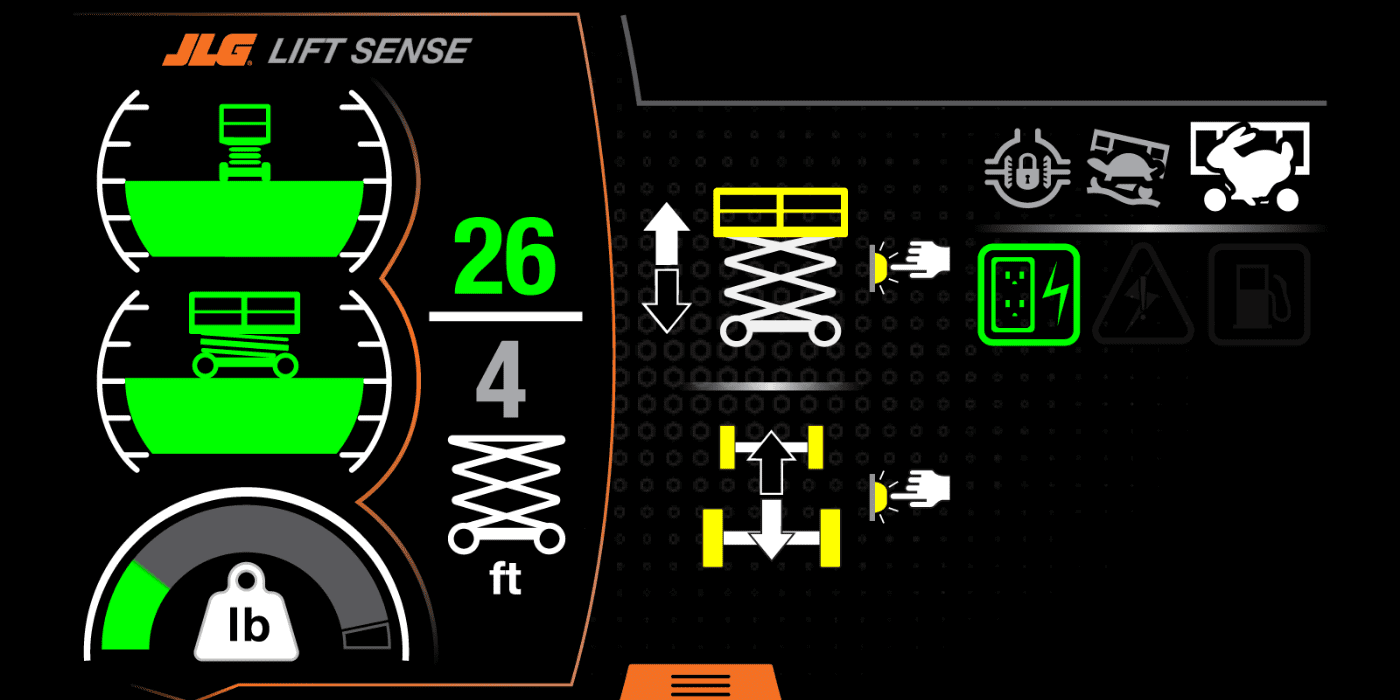

An industry-first platform control box LCD screen will remove that guesswork by providing live feedback for operators.

The new LiftSense display will show side-to-side tilt, front-to-back tilt, how much weight is on the platform, the current height of the platform, and the maximum height you can raise your MEWP by taking those factors into account, says Rafael Nunez, senior product manager for scissor and vertical lifts.

“You'll be able to see if you should take a little bit less material with you or if you need to get to a spot that's a little bit more level on the job site so that you can get the full height,” Nunez says.

The covered, ruggedized display is tested to withstand tough job site conditions, and it will be standard on all JLG electric rough-terrain scissor lifts, select rough-terrain scissor lifts, and the 670SJ self-leveling boom lift, with expected availability by the end of 2020.

Cross-over of Safety Technologies

Outside industries, including the defense, public safety, and on-highway vehicle markets, are influencing the next set of safety features for access equipment.

“What happens is you get spin-off technologies that we can apply in the access industry,” says Rob Messina, senior vice president of global product development.

He says technologies in those industries, such as object detection sensors, back-up cameras, and seat belt/lanyard attachment verification systems, all have the potential to be adopted and become standard for MEWPs and telehandlers in the near term.

“These are technologies that progressively improve the machine's ability to provide safe solutions,” Messina says.

Problem: How do I minimize risks while navigating my surroundings?

Solution: Increase awareness of potential obstacles.

Just like the blind-spot detector in your car, platform sensors can warn operators of objects that are in their path of movement.

The SkySense™ enhanced detection system, available on most JLG boom and scissor lifts, will produce an audible and visual alarm that will increase in frequency and reduce the speed of the machine as you get closer to an object, eventually stopping the machine once you’re too close.

At that point, the operator must manually override the system to continue maneuvering the platform.

“You're now inching toward that object instead of coming in fast,” Nunez says.

It’s important to note that the sensors only look in the direction of travel and the warning zones are scalable based on joystick input, Nunez says.

“It takes a lot of software and thought to do something like this,” he says.

More Steps Toward Connected Job Sites

Hearing about the autonomous work sites of the future where machines communicate to each other and the people that manage them can sound like some far-off concept that’s still years down the road.

But increasing pieces of fleet connectivity, in ways that are fairly simple to implement, are moving access equipment closer to that ultimate destination.

“If we focus on moments of autonomy that are practical and digestible, we advance the cause in the industry toward something bigger,” Nerenhausen said in the article.

Problem: How do I prevent unnecessary downtime?

Solution: Remotely check operational status and diagnose equipment failures.

Is your electric scissor lift ready for a full shift’s work? It’s often hard to tell, before the machine unexpectedly quits.

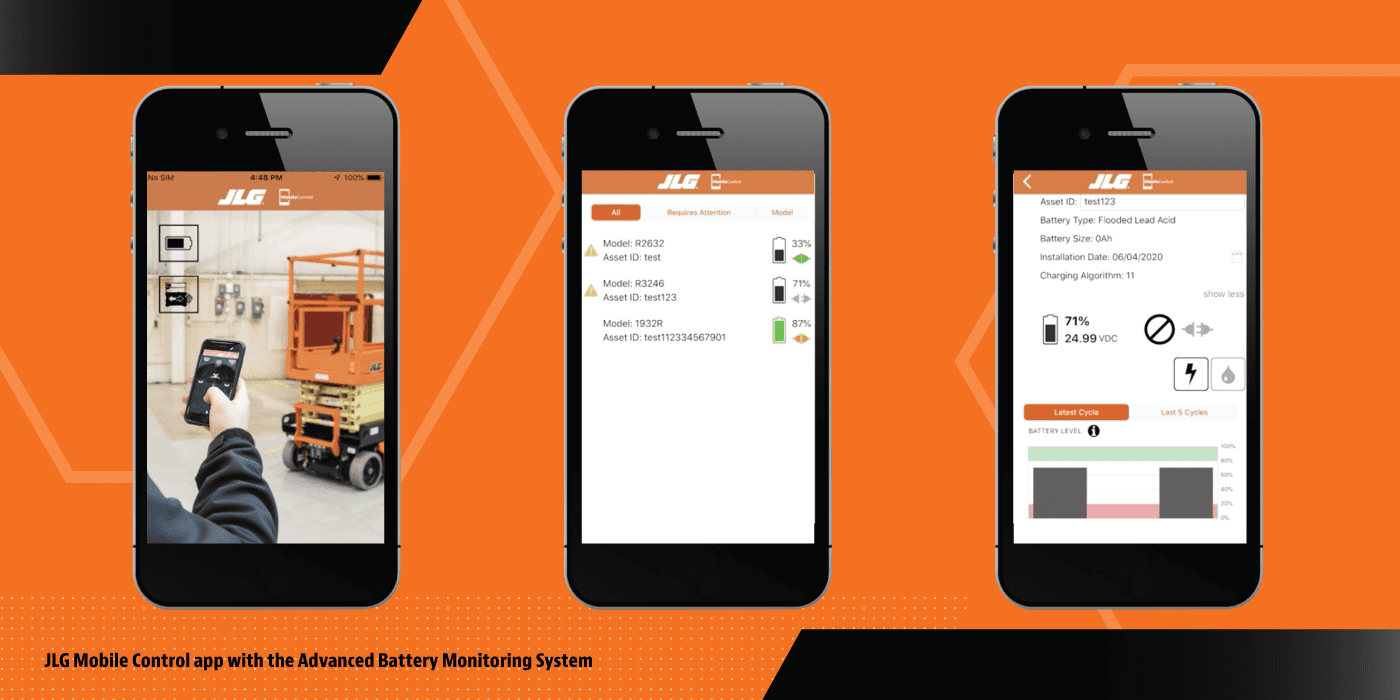

Now you can view important battery status information, including current state of charge, charging cycle history, and when maintenance needs to be performed, with just a tap on your smartphone.

It’s a new feature in the Mobile Control app for ES and R Series scissor lifts, made possible through the Advanced Battery Monitoring System (ABMS).

“This allows users to make fleet-level decisions without the need to touch individual machines to collect data on a one-to-one basis,” says Stefan Eschelman, senior product engineer.

The app, which also allows operators to drive scissor lifts remotely, provides easy-to-understand snapshots about whether your scissor lifts are ready to operate or what problems need to be addressed.

“This is a simple step toward changing expectations of how users can interact with our machines without overburdening them with the obscure promise of ‘connectivity,’” Eschelman says.

Remote diagnosis of problems is also possible for CAN bus-equipped MEWPs and telehandlers.

When you call your rental company or dealer about an equipment failure, the service tech can check the machine’s performance and review fault codes using the new remote analyzer reader (RAR) through the ClearSky™ telematics web portal.

This enables the service tech to make sure they have the right parts and tools to get the machine up and running quickly when they come out to your site.

Driving Designs Through User Feedback

In the past, new MEWPs and telehandlers were primarily designed with an emphasis on developing best-in-class specs.

That’s all changing, says Shashank Bhatia, senior director of global product development.

“We have now shifted and put a lot of emphasis on getting customer-based input,” Bhatia says. “We call this customer-inspired innovation.”

New access equipment designs will give more attention to the needs of the user, and not just the rental company or dealer, Bhatia says.

Problem: How can I lift materials higher without using a crane?

Solution: Find an alternative with today’s telehandlers.

Typically, if you needed to move materials higher than six stories, you had no choice but to invest in a crane.

But crane rentals are expensive.

They are costly to transport and assemble, and they require a certified crane operator.

John Boehme, senior product manager for telehandlers, says for years, users have been requesting a telehandler that could extend higher and reach farther to serve as a crane alternative.

With a 75-foot boom that can lift materials up to eight stories, the new 10,000-pound 1075 telehandler gives users that ability.

And unlike a crane, the 1075 can lift up-and-in to place materials exactly where they’re needed without requiring the use of a forklift to reposition the pallet.

“You can reach 60 feet inside a structure,” Boehme says. “You're able to have better precision placement.”

If materials or an HVAC system need to be placed on top of a building, operators can control the boom remotely from the roof.

Also, no specialized trucks or trailers are needed to get the 1075 to the job site. At less than 45,000 pounds, the 1075 can be transported on a common step-deck trailer.

Though it’s a big boy, it can get around a busy site with ease, Boehme says.

“We were able to provide maneuverability that's equivalent to or better than a smaller 10K or 12K machine,” he says.

Providing the Total Package

In the end, the defining moment of the access equipment industry will be about more than just offering the product.

It will be about developing comprehensive resources for access equipment owners, operators, and service providers that progressively fix problems before they occur.

“Life-cycle management really is what we're driving toward,” Nerenhausen said in the Lift and Access article.

Rapidly maturing technologies and data analytics are turning concepts and ideas into reality.

“Where you’re going to see this evolve is through key sensors that provide additional pieces of feedback and information that can be used to more quickly diagnose a symptom,” Messina says.

The goal: Continue to make it easier and safer for access equipment users to get their jobs done.

“Through the next fleet cycle, you’re going to see a lot of change,” Messina says. “Not just at JLG, but across the industry in the next five years.”

Problem: How do I know if this is the right machine for the job?

Solution: See for yourself with your smartphone.

You’re on a large site, ready to work, trying to figure out which MEWP you could fit through a narrow entryway and still give you the access you need.

You could go locate one of the machines on rent and try it out. This will take time and perhaps even multiple machines until you find the appropriate one for the task.

Or you could hold up your smartphone and quickly see for yourself with the free Augmented Reality (AR) app.

“It gives a person the power to visualize equipment information, when and where they need it,” says Ara Eckel, senior product marketing manager for connected solutions.

Users can place a scaled 3D machine in the actual work environment captured in the app. They can raise and lower the machines and move them through doorways and around obstacles.

The app also allows users to see what accessories are available for a particular machine and what different symbols on the decals mean, as well as familiarize themselves with a machine’s controls.

It can also provide inspection assistance.

“You hold the app on your phone up over your machine, and it's going to put pins over all the spots where you need to perform your annual inspection,” Eckel says. “As you click on those pins, you can now take a look at the information in the pin drops and actually perform the inspection in a step-by-step way.”

The AR app is available to download for scissor lifts, boom lifts, and low-level access machines, and it will be available for telehandlers in the future.

Want to stay up to date with industry news and trends similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.