Telehandlers are used to lift, carry and place materials around job sites; however, it is up to the operator of the machine to assure the material it’s lifting, placing or carrying is within the rated capability of the unit. Since telehandlers also have the unique potential to extend those materials away from the vehicle with the telescoping boom, knowing the weight and center of gravity (cg) of the material being lifted becomes even more important.

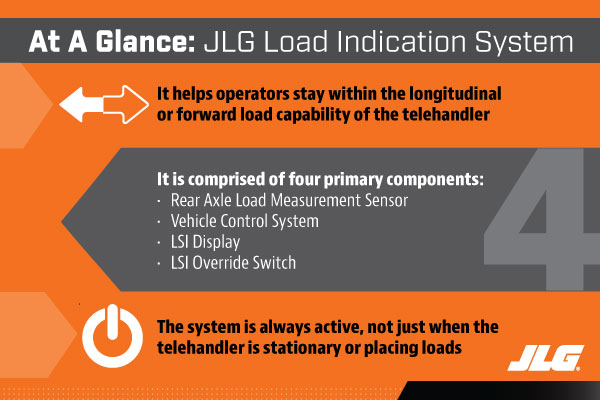

While there is no substitute for knowing the weight and cg of the material being lifted, placed or carried to assure the movement can be executed, JLG offers an operator aid on select models that helps the operator stay within the longitudinal or forward load capability of the telehandler – Load Stability Indication (or LSI).

How does it work?

The LSI system has four primary components. The first is a sensor attached to the rear axle, which is able to measure the weight applied to the rear axle of the vehicle.

The sensor on the rear axle provides the rear axle load measurement to the vehicle control system; the second part of the LSI system. The vehicle control system is the brain of the vehicle, collecting and transmitting data and commands to many parts of the vehicle.

The vehicle control system sends data to the LSI display in the cabin of the vehicle, which is the third part of the LSI system. It is the LSI display that provides the operator a visual indication of the forward stability status of the vehicle.

There are six levels of indication in the display, progressing from green (load within capability) to orange (load capability nearing limit) to red (load capability at the limit). If the forward load capability of the vehicle is reached, a red lamp is illuminated on the display. When this happens, an audible alarm is activated, and the vehicle control system will stop and prevent further activation of many of the vehicle hydraulic implement functions. The only implement functions available to the operator to correct the stability of the vehicle are retract boom (in) and lift boom (up). When stability of the vehicle has been improved, the audible alarm will turn off and the display will return to orange.

The fourth and final part of the LSI system is the LSI Override Switch, which the operator may choose to use in order to continue operating the vehicle with the red lamp illuminated and hydraulic implement functions inhibited.

Maintenance with an LSI System

Maintenance with an LSI System

The LSI system must be calibrated on every vehicle initially and verified periodically. Differing attachments on the vehicle do not affect the calibration; however, things such as wheels and tires with significantly different weights, such as different fill media, may affect the calibration. The calibration procedure, found in the applicable service manual, must be followed to assure the system operates reliably.

Owners and operators of JLG telehandlers will find the addition of the Load Stability Indication system an aid in assisting these machines to be operated within their rated capability.

Additional Considerations

The LSI system is always active, not just when the telehandler is stationary and placing loads. Lowering the boom from a high angle, for example, is a function that may quickly affect the forward stability of the vehicle. For that reason, the LSI system considers multiple factors for each boom lower request from the operator and determines how best to react to the request. Depending on stability level, boom extension, boom angle and level of activation requested, the vehicle control system determines the appropriate acceleration and speed at which to execute the boom lower request. The operator still has full control to stop the action at any moment, but the vehicle control system will determine the appropriate deceleration to terminate the boom lower request.

Telehandlers satisfy such a diverse range of job site needs, such as unloading trucks, transporting materials, placing material at height, performing farm duties in crop harvesting and feeding, as well as a myriad of other uses. Due to their multi-tool use, owners and operators of JLG telehandlers will find the addition of the Load Stability Indication system an aid in assisting these machines to be operated within their rated capability.

Want to stay up to date with industry news and trends similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.