JLG Industries, Inc.

JLG Industries, Inc.

World-leading access equipment manufacturer

____

McConnellsburg, PA

When exposed to crystalline silica, workers are at a higher risk of developing lung, kidney and autoimmune diseases. According to OSHA’s respirable crystalline silica standard for construction, employers must provide proper training and PPE for any worker who may come in contact with the substance.

What is crystalline silica?

Crystalline silica is a mineral found in both natural and man-made materials. The most common type of crystalline silica is quartz. Because it is such a fine mineral, crystalline silica can be breathed in during common tasks like sand blasting, cutting concrete blocks and grinding mortar.

What types of material is crystalline silica found in?

Workers may encounter silica in naturally occurring materials like sand, rock and stone. It’s also present in many synthetic materials used in construction tasks, including concrete, brick, mortar, tile, block and artificial stone.

How do you protect employees from silica dust on the job?

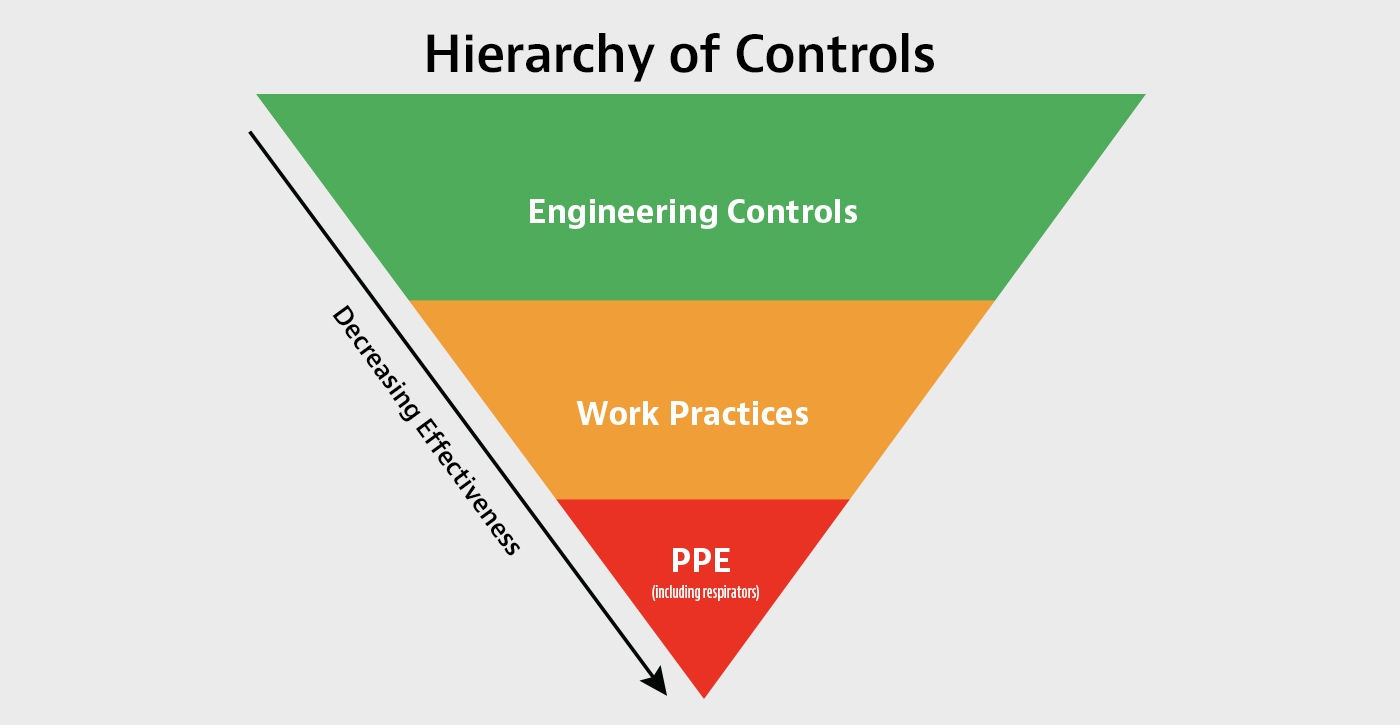

To protect workers, it’s important to follow OSHA’s hierarchy of controls, which aims to help organizations avoid injuries, illnesses and incidents by following a predetermined set of steps. These steps help employers control hazards and create a healthy work environment.

*Source: Occupational Safety and Health Administration

The first level of defense against silica dust are engineering controls. These types of controls eliminate or isolate silica dust to the area where it originates. Some of the most common engineering controls include:

- Water or foam: This method uses water or foam to keep silica dust out of the air. By wetting down a surface before cutting or grinding a material containing silica dust, you can minimize the amount of dust released into the air.

- Vacuum dust collection: This method collects dust at the point where it’s made with a vacuum connected directly to a tool.

- Isolation: This method protects an employee from silica dust through the use of a barrier, like the cab of a piece of heavy equipment.

The second level of defense is work practices, which means performing a job in a way that minimizes silica dust exposure. This requires training, as employees need to be able to determine the effectiveness of engineering controls and address them if they’re not working properly. Other positive work practices include scheduling dusty tasks when fewer employees are present and using proper methods when cleaning up silica dust.

The final level of protection is PPE, like respirators and dust masks. This type of protection should be used in combination with engineering controls and work practice controls for the most effective silica dust protection.

Want to stay up to date with industry news and trends similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.