John Boehme

John Boehme

Senior Product Manager - Telehandlers

____

JLG Industries

Crews constantly are tasked with becoming more efficient on the job site — and the key to achieving that is well-maintained equipment. For a telehandler to operate at full capacity, it needs to be in proper working order. Knowing when and what to check on your telehandler will also help reduce unplanned downtime.

Follow these four preventive maintenance tips outlined in the machines’ Operation and Safety Manuals before using JLG® and SkyTrak® telehandlers to keep them in peak operating condition.

Tip 1: Be prepared to perform maintenance

Before beginning the maintenance checks, follow the shutdown procedure. Put the lever in neutral, set the parking brake, lower the forks, put the mast in its vertical position, turn off the telehandler and remove the key.

The telehandler must also be level to ensure your fluid readings are accurate. Don’t perform any maintenance if the engine is running.

Tip 2: Complete all required maintenance tasks

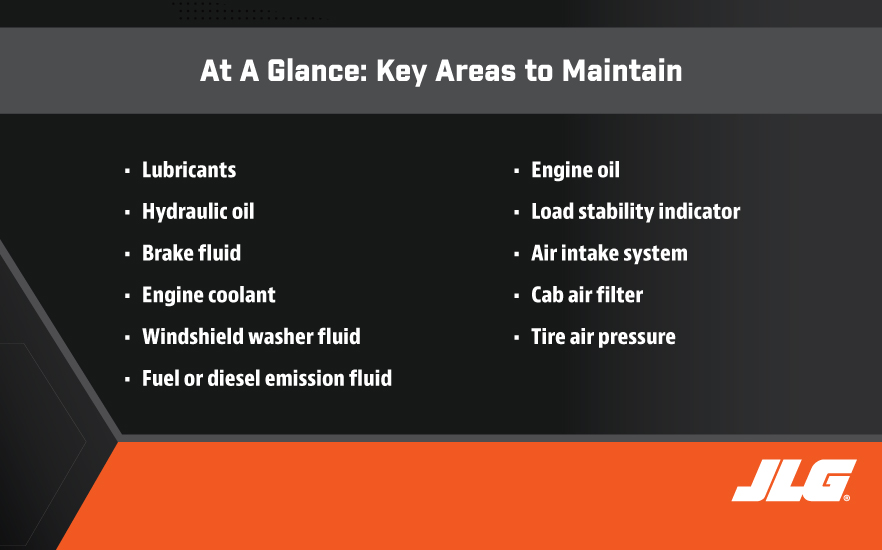

Once the telehandler is level and the engine is cool, check all of the lubricant levels. Before lubricating, clean the lubrication fittings. After you grease it, cycle through the functions several times to help distribute the lubricants. You should also apply a light coating of engine oil to all of the linkage pivot points.

To check the hydraulic oil level, look at the sight gauge to ensure the oil level is visible in the gauge window. If it’s not, remove the fill cap and add hydraulic fluid until the oil is up to the center of the gauge and replace the cap.

The brake fluid level should be between the maximum and minimum marks on the brake reservoir. If the fluid is low, the telehandler will need to be serviced before it’s operated.

To check the engine coolant level, open the engine cover and check the surge tank. The coolant should be between the “Full” and “Add” marks. If it’s not, add engine coolant. The windshield washer fluid should be visible in the reservoir.

Look at the fuel and diesel emission fluid (DEF) gauges on the right side of the cab’s instrument panel, and fill the tanks as needed. To check the engine oil level, open the engine and check the oil mark on the dipstick.

To check the Load Stability Indicator (LSI), remove any attachment and retract and raise the boom. Press and hold the LSI override switch and the two control buttons. The LSI indicator LEDs will light up sequentially and then repeat if it’s successful.

When it’s time to check the air intake system, open the engine cover and remove any dust from the vacuator valve by squeezing the bottom of the valve. Once you’re finished, close the engine cover.

For telehandlers with cab air filters, remove the two thumb screws from the panel to take out and inspect the filter. If it’s damaged, it will need to be replaced.

To maintain the tire air pressure, remove the valve stem cap and check the pressure. Add air if needed and then replace the cap. If there’s any damage to the tires, they will need to be replaced.

If any of the maintenance test results can’t be achieved or if the system isn’t working properly, the telehandler must be removed from service and repaired before being operated again.

Tip 3: Know when to perform maintenance

Following a maintenance schedule allows you to keep the telehandler in proper working order before there is a failure or issue. Here’s the list of when to check and/or change each component:

- Every 10 Hours: Fuel, tire condition/pressure, engine coolant level, engine oil level, hydraulic oil level, drain fuel/water separator, brake fluid level, DEF level (for Ultra Low Sulphur Diesel – ULS – fuel), air cleaner and additional checks

- First 50 Hours: Wheel lug nut torque, axle oil level, wheel end oil level, hydraulic tank breather, hydraulic filters

- Every 50 Hours: Lubrication schedule, washer fluid, LSI system, cab filter

- First 250 Hours: Axle oil, wheel end oil, dual pump drive oil, drop box oil

- Every 250 Hours: Lubrication schedule, axle oil level, wheel end oil level, drop box oil, dual pump drive oil, boom wear pads

- First 500 Hours: Engine oil and filter (for ULS)

- Every 500 Hours: Hydraulic tank breather, hydraulic filters, wheel lug nut torque, engine oil and filter (for ULS)

- Every 1,000 Hours: Axle oil, wheel end oil, air intake system, fuel filters, battery, engine oil and filter (for ULS), dual pump drive oil, drop box oil, park brake, LSI calibration, fan belt

- Every 1,500 Hours: Hydraulic fluid and filters

- Every 2,000 Hours: DEF tank filter (for ULS), engine coolant strainer (for ULS), crank-case vent filter

- Every 4,000 Hours: DEF pump filter (for ULS)

- Every 5,000 Hours: Engine valve lash adjustment

These intervals are for normal conditions and usage. There might also be additional checks needed depending on your machine’s daily usage or configuration, so reference the machine’s Operation and Safety Manual.

Tip 4: Educate operators on proper maintenance

Maintenance needs to become a regular part of your team’s schedule if it isn’t already. That includes providing the proper education and training on how to perform maintenance tasks.

JLG offers training and educational information to help with your telehandler maintenance, click here for more information, along with OEM, aftermarket and remanufactured parts to get your equipment back up and running. To learn more about JLG’s parts, service and support, including accessing Online Express, JLG’s online parts purchasing system and resource center, click here.

Do you want to stay up to date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.