Nate Hoover

Nate Hoover

Director - Product Management, Boom Lifts

____

JLG Industries

If you followed JLG news in 2020, you may have seen the introduction of the JLG® 670SJ self-leveling boom lift at CONEXPO-CON/AGG — a machine that boasts a very unique feature that allows the machine to automatically level on grades up to 10 degrees when in self-leveling mode. This self-leveling technology is not only distinctive in that it enables the boom to do something no other boom can do, but also in that its development is a story of customer-inspired innovation.

Let me explain…

Recognizing a challenge

We developed the self-leveling capability as a result of our teams watching how boom lifts work on job sites, as well as talking with operators that use this type of equipment every day.

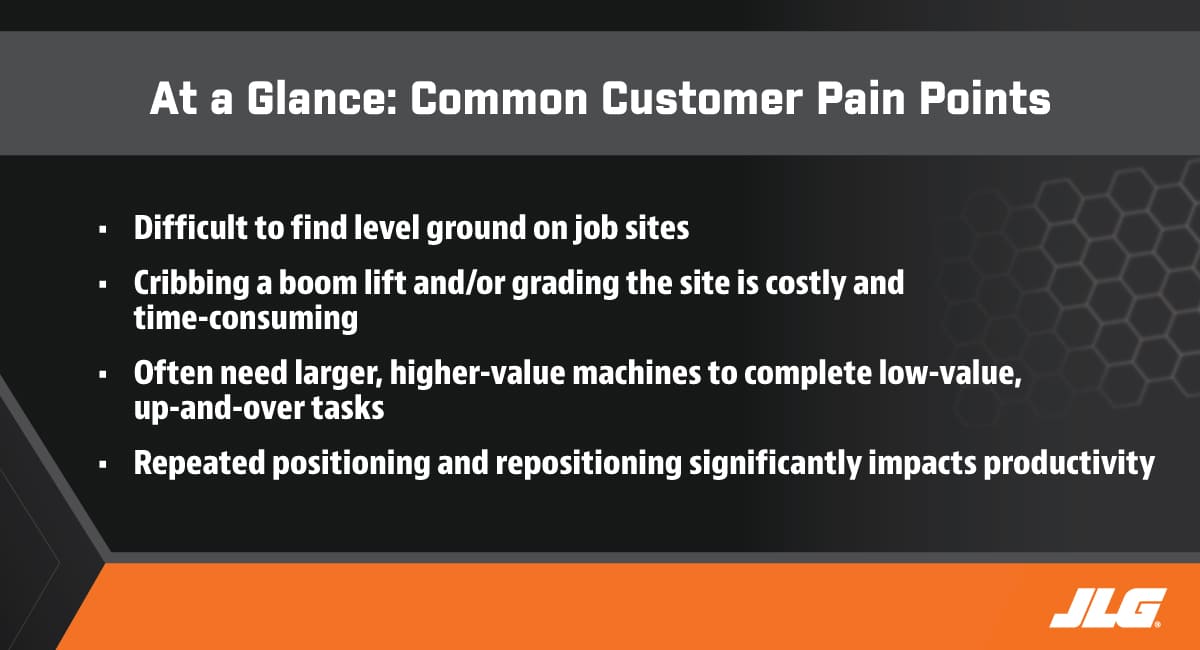

Quite frankly, there are many applications and working environments that can be rather challenging for a traditional oscillating axle boom lift to work in. This is because these machines are only rated to work on firm, level surfaces with 5 degrees or less of grade, and most job sites aren’t flat — nor will every job site have an improved surface.

These are the type of situations that lead to operators putting in a lot extra effort to get work done at height. In many cases, workers come up with creative ways to make their boom lifts productive on real-world job sites, such as:

- Constant repositioning

- Removing small areas of earth with a compact loader to level the ground

- Employing a longer boom lift to reach the work area from a level spot beyond where they’d ideally like to place the machine

- Using multiple boom lifts

- Cribbing the machine on a localized platform to attain a level work surface

- Shoring up the ground or stone leveling a raceway to attain a level work surface

Although most of these options can get the same work done, they come with hidden costs, often requiring excessive labor, long-term fixed space utilization, specialized experience and/or larger footprint requirements. They also often result in the low-value utilization of a high-expense asset.

None of these are ideal scenarios, especially when budgeting for bid/spec projects where the margins are already tight.

Developing the right solution

At JLG, we believe that we have a responsibility to be more than an aerial equipment manufacturing company — we are committed to understanding our customers’ job site challenges and partnering with them to develop solutions that deliver tangible benefits to their businesses.

Every day we strive to put this belief into action, and the path to developing the 670SJ boom lift is an example of this commitment.

Here’s how: The journey started in 2015 when our technical team initiated a project to explore the viability of developing a boom lift with a smart “suspension” system. We built a scale model prototype to show at Bauma 2016 where we asked customers to provide feedback on the machine’s overall design.

Taking what we learned from these conversations, JLG engineers set out to create a full-size concept machine within a year. The goal was to increase a lift’s capability on slopes up to 10 degrees in any direction with the boom elevated, as well as to improve the lift’s ability to traverse uneven surfaces — while keeping the boom level to improve traction capability on sloped ground.

JLG succeeded, and we displayed the JLG 460SJ concept machine at CONEXPO/CON-AGG 2017, and again, we asked customers to provide feedback.

Focusing our efforts

Armed with more customer insights and information, our team then started down the product development path, which began with industry research to gain application insights. We focused first on the needs of trades that we knew could really benefit from a different type of solution.

We then conducted extensive testing and field trials with customers at three key stages (Early Design, Value Observations and Control Evaluation) during which we solicited feedback on the machine’s ease of use, as well as gathered safety and productivity metrics.

As the journey continued, we worked with customers to best understand Adoption Detractors and Adoption Promoters, as well as to put together value estimates. Throughout the process, we uncovered many important insights.

Realizing the advantages

Self-leveling technology is designed to adjust the boom lift’s chassis to the ground conditions (rather than trying to adjust the ground conditions for the machine). We developed it as a fully integrated solution to make sure the machine automatically levels at all times, even when driving the unit elevated.

As operators tested our self-leveling boom lifts, we asked them for feedback that could help us get this product to market. They told us that some of the advantages this technology offered them were:

- Fewer chances for dropped tools

- Operators and occupants were more stable during travel due to reduced bouncing of the unit as it traversed uneven terrain for improved operation and reduced fatigue

- Safety features with improved productivity, which translated to more work getting done

- Reduced platform occupants’ fear of heights due to a smoother ride

- Offered greater stability - operators reported feeling more secure while driving

Receiving input like this allowed us to validate the design and make important design modifications where necessary to ensure that when we launch the product, it would be the right solution for our customers.

Bringing it to the market

By late 2019, we knew we had a product that was nearing launch readiness. Our aspirations of designing a safer, more productive solution to a number of common customer pain points on slopes up to 10 degrees were realized with the introduction of the JLG 670SJ self-leveling model.

We purpose-built this model to:

- Traverse substantially uneven ground, with full functionality while driving at height, to get closer to the work area quicker

- Minimize the need to crib and/or grade the work area

- Eliminate the trial and effort of repositioning to find a level work area

- Enable the boom lift to get closer to the work area to maximize reach capabilities and reduce the need for larger, higher reaching lifts as backup

- Decrease platform movement during travel, which may reduce operator fatigue and minimize the potential for objects bouncing around and/or out of the platform

- Fully comply with ANSI 92.20/CSA B354 standards with an industry-leading allowable operating slope

Looking to the future

When John L. Grove started JLG in 1969, he was driven to develop a safer way to work at height. And, we believe that the 670SJ self-leveling boom is evidence that this core value is still alive within our company, fueling our passion to move the access industry forward. It is a step change for the industry — a technology that will truly transform the way people work at height by increasing productivity and enhancing safety best practices. It also highlights that customers are our greatest priority, and our dedication to involving them throughout our development process offers proof of that.

The 670SJ is the first JLG boom lift available with self-leveling technology, though we don’t expect it will be its last.

To learn more about the introduction of the 670SJ self-leveling boom at CONEXPO-CON/AGG 2020, click here.

Do you want to stay up to date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.