JLG Industries, Inc.

JLG Industries, Inc.

World-leading access equipment manufacturer

____

McConnellsburg, PA

For operators of mobile equipment, transporting and placement of loads could be a daily activity. The job site varies as frequently as the applications.

However, a common theme in their workday routine is that proper planning is important to achieving the desired results in a timely and safe manner. They need to assess the vehicles capabilities and accessories needed for the tasks at hand.

Typical questions an operator may need to consider are things like:

How are the loads packaged and their weight?

Will they need to use a fork carriage or some other attachment?

How high and how far will they need to retrieve or place the load?

A telescopic handler will assist at placement and retrieval of loads at heights that can’t be matched by wheel loaders, skid steers or vertical mast forklift trucks. While a telehandler can provide obvious load retrieval and placement advantages, it also creates distinct dynamic features that must be considered. The telescopic quality of the specific machine adds another layer of complexity when planning the task at hand. Understanding the elements that go into a safe and successful load placement are vital to effective use of a telescopic handler.

Understanding the elements that go into a safe and successful load placement are vital to effective use of a telescopic handler.

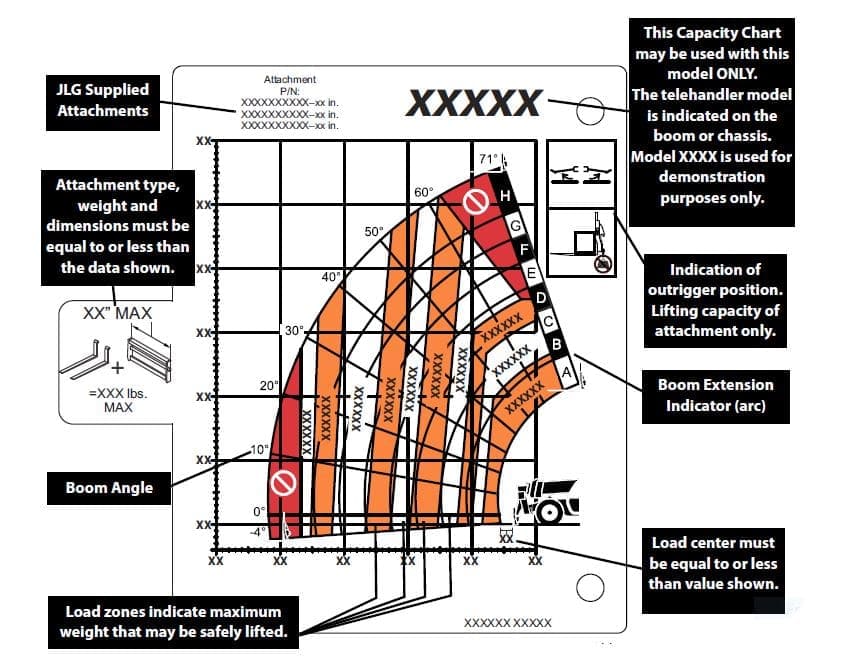

Every unit is equipped with a load capacity chart for the attachment that is being used. Some attachment examples are a fork carriage, bucket or truss boom. All load capacity charts are developed and constructed under the format prescribed by the safety standard requirements of the specific region in which the machine will be used.

The load capacity chart contains a grid showing reach from the front face of the front tire and heights relative to the vehicle’s supporting surface. The operating range of the telehandler reflects minimum and maximum boom angles as well as fully retracted and extended boom positions. The operating envelope is located relative to the load center position of the attachment being used. Fork carriages place the load center on the supporting surface of the forks and typically at a 24 inches horizontal position relative to the vertical front face of the fork. This particular load center distance equates to a 48 inch length load.

A sample load capacity chart looks like this.

To effectively utilize the load capacity chart, the user must initially determine some basic criteria:

1. The weight of the product or material being elevated

2. Desired height or reach they need to achieve

3. Your specific telehandler load capabilities

Once the weight and telescopic handler model have been successfully paired, the user must assess the load placement or retrieval position. Boom angles and extensions are an integral part of every load capacity chart as are the corresponding visual indicators provided on each unit. The operator will use boom angle and extension to place or retrieve the intended load at the required height and reach.

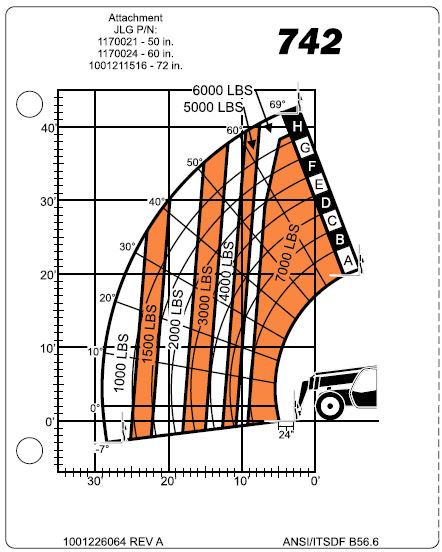

As an example using the model specific load capacity chart below, the operator needs to place a 5000 pound load at a height of 20 feet and a reach of 10 feet. The material is palletized with a load center of 24 inches. Utilizing a fork carriage and a properly selected model, the operator reviews the load capacity chart and determines that the boom angle indicator should read 40 degrees and the boom extension, visible from the side of the boom, will be the black “D” zone.

Keys to successfully and safely navigating through daily activities are:

- Understanding the load capabilities of the vehicle being used

- Familiarity with the jobsite layout and employ the features provided on board the machine.

The load capacity chart provides the operator with guidance that allows them to confidently utilize their telescopic handler in a productive and safe way. By properly planning and avoiding risky behavior, the operator can finish the day safely and be ready for another day of productivity.

Want to stay up to date with industry news and trends similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.