Rotating telehandlers have long been popular in Europe, where city streets are often narrow and curve through tightly packed buildings. With a trend towards urbanization in North America — and less open space as a result, contractors are turning to rotary telehandlers to complete pick-and-place jobs where the telehandler must be stationed in one place, without frequent movement.

The rotating telehandler concept is relatively new to the North American construction industry, so let’s take a look at how they fit into the market…

The tale of two telehandlers

Telescopic handlers, or telehandlers for short, were first developed to replace vertical-mast forklifts and forklift trucks because these machines’ telescoping booms enable operators not only to reach high but also to reach out. This allowed for loads of job site materials, like bricks, to be raised up and into 4-5 story buildings.

Telehandlers have evolved since their introduction into the market, and today’s models are defined as either fixed or rotary, depending on whether or not the machine is equipped with a rotating turret.

Fixed-boom telehandlers became extremely popular for pick-and-carry work around construction sites thanks to their ability to lift and extend loads directly in front of them.

However, while applications might be the same, the need to pick-and-place material on very congested worksites, makes the right equipment selection for the job very different. This unique requirement led to rotary telehandlers, or “rotos” as they are affectionately nicknamed, to increase in popularity when telehandlers need to park in one spot and lift materials without having to travel or maneuver to pick-and-place loads.

Rotation offers an advantage

Rotating handlers are designed to lift, extend and rotate 360 Degrees, adding a new layer of functionality during operation. This capability is particularly useful on confined, space-restricted job sites where there is little room to maneuver a traditional (fixed-boom) telehandler and ongoing machine movement would present a major challenge for operators.

Simply, rotos’ horizontal rotation capabilities offer the ability to work at height with little, or no, repositioning. This versatility increases an operator’s productivity while reducing space required for equipment on a job site.

An alternative to cranes

Along with their rotational capabilities, rotary telehandlers generally boast very high lift capabilities, with most models able to work at heights well above 75-ft. Because these machines are not only able to lift but also to rotate materials into place, this gives them crane-like performance.

In fact, rotary telehandler capabilities overlap those of truck-mounted and small rough terrain cranes. That’s because, if equipped with a lifting hook orwinch, these telehandlers can also handle suspended loads.

The advantages of rotating telehandlers over these types of cranes are that rotos come without the need for a licensed crane operator, when lifting less than 2,000-lbs (in most cases), in North America, reducing the cost to rent and operate these machines on job sites. And for equipment owners, rotary telehandlers come at a much lower acquisition cost than cranes, offering an attractive, affordable price point for those looking to add these machines to their fleet.

A 3-in-1 machine

We’ve taken a look at how rotating telehandlers can be used in applications where fixed-boom telehandlers wouldn’t be efficient, but the work still requires telescoping capabilities.

And, we’ve explained how these rotary models are more cost-effective than cranes.

But, that’s not all, there’s one more advantage of these rotating models to mention. In some applications, these machines can act as a MEWP (mobile elevating work platform). That’s because, when equipped with a platform attachment, these telehandlers can offer the capabilities of an aerial work platform — lifting operators and tools up to complete work at height.

The ability to be a “3-in-1” machine is a key factor in the growing popularity of rotating telehandlers in the U.S. With their heavy lift capacities, extended reach capabilities and, most importantly, 360-degrees of continuous rotation, market acceptance is increasing for rotary telehandlers — and with more awareness, we believe they’ll soon become a mainstay on construction sites around the country.

JLG now offers rotating telehandlers

JLG has long been a market leader in the fixed-boom telehandler space. And as we’ve seen demand for rotary telehandlers increase, we are diversifying our telehandler portfolio by expanding into this growing category

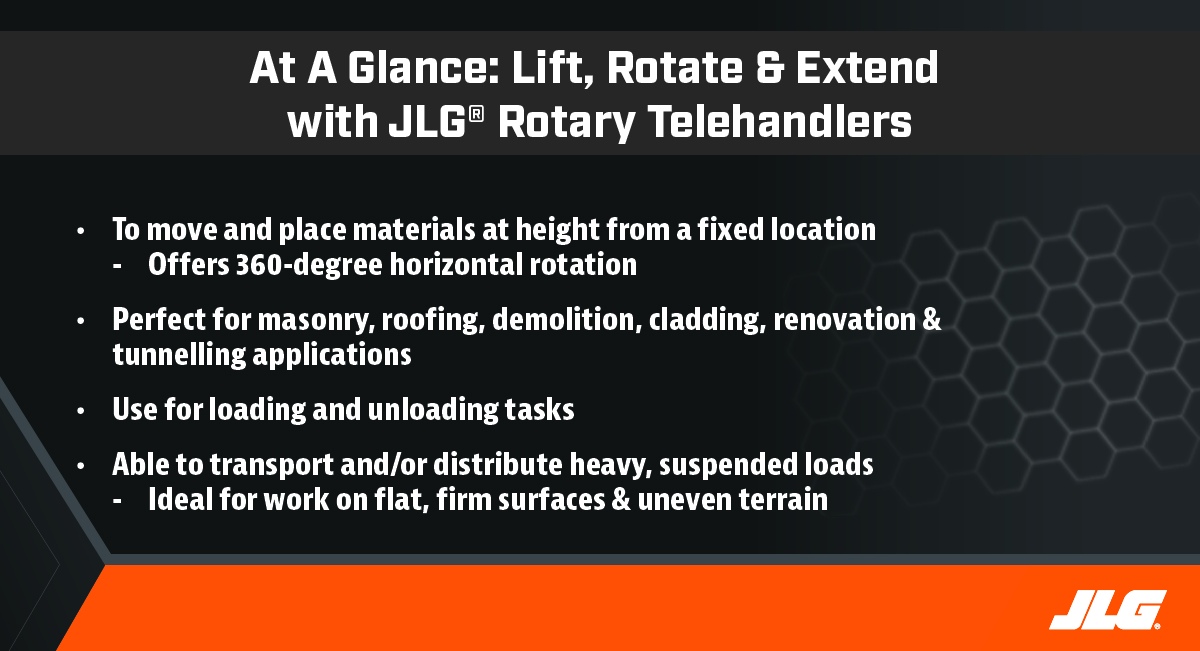

To do this, JLG has introduced the R1370, R1385 and R11100. This new line of JLG rotos will transform the way work on congested job sites is done by allowing operators to pick and place materials at height from a fixed location with 360-degree horizontal rotation.

JLG rotating telehandlers began production in late 2021 and will be available for purchase in the U.S. region in 2022. These machines are purpose-built for masonry, roofing, demolition, cladding, renovation and tunnelling applications, and they are well suited to handle loading and unloading tasks on these types of job sites. They are also designed to transport and/or distribute heavy, suspended loads on flat, firm surfaces and uneven terrain.

Interested in learning more about JLG’s rotary telehandler offering? Click here.

Do you want to stay up to date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from #DirectAccess with newly posted content so you never miss important information.