Perfect for accessing hard-to-reach work in small spaces in high places, the market demand for “micro” mobile elevating work platforms (MEWPs) is growing rapidly worldwide. At JLG, we categorize these small-scale lifts as our low-level access product line. Low-level access lifts are considered ladder and scaffolding alternatives that deliver a maximum work height of 20-ft and weigh less than 2,000 lb.

These products are primarily used in applications where one would historically use a ladder or scaffolding because they can be easily rolled through a facility and assembled or disassembled quickly, allowing workers to access catwalks, landings and other hard-to-reach areas. These lifts are ideal for applications including mechanical and electrical work, HVAC and ductwork, hanging drywall, painting, retail refit and display, construction finishing work and cleaning.

There are three key trends accelerating demand for and adoption of low-level access lifts, including:

- The first is that more and more companies are looking to replace ladders and scaffolding with products that offer a safer way to work at height. Ladder falls and overuse injuries as the result of ladder use have many negative outcomes. In addition to employee injury, falls can lead to lost time, reducing productivity and costly workers compensation claims. Safety conscious companies, including JLG’s parent company Oshkosh, are committing more and more to the elimination of ladders when other alternative exists.

- The second trend is urbanization. With less open space, and buildings getting taller and narrower, there is a greater need for products that have a small footprint, are lighter weight for use on sensitive flooring and that can fit into and moved between floors in elevators for finish and fit out construction work as well as ongoing maintenance.

- The final trend is an increased focus on environmental considerations. Human- and battery-powered lifts run quieter, as well as eliminate or reduce emissions altogether, making them suitable for use everywhere from libraries and hospitals to office buildings and universities.

As the popularity and demand grows for using small-scale lifts, instead of ladder and scaffolding, opportunities in the market for low-level access solutions continue to develop. Below are responses to the most frequently asked questions about “micro” MEWPs in order to better understand these types of machines…

Are there different styles of micro MEWPs? What are some of the more common configurations/ratings/access capabilities?

Low-level access lifts aren’t one-size-fits-all. There are many options to choose from, whether a worker needs a highly portable lift or an eco-friendly crank lift. These variety in these types of lifts allows people to fit into tight spaces and reposition easily, while being lightweight enough for use on sensitive flooring and in elevators.

Human-powered lifts are lighter weight and quieter than their battery powered counterparts.

While still small, battery-powered units tend to have a slightly larger footprint, are heavier and have a higher platform capacity, allowing the user to bring more tools and materials with them to the work area at one time, reducing the number of times they need to ascend then descend during the workday.

What are the pros (or cons) of these types of machines?

Operators in low-level equipment can use both hands comfortably to do work safely at height, a full 360 degrees. This isn’t the case with ladders, where workers often must use one hand to stabilize themselves at height, leaving only one hand free to perform a task. This equipment also features portability benefits. Low-level access equipment can be lowered and moved from one location to another, making it easy to perform multiple tasks throughout a facility in less time.

The non-powered realm of low-level access lifts includes models that feature a patented stored power lift system that requires no batteries, hydraulics, oil or controls. Because no hydraulics or motors are involved, these eco-friendly lifts are leak-free and operate quietly, making them a preferred piece of equipment for work in environmentally sensitive areas, such as clean rooms and data centers, as well as in hospitals, schools, libraries and office buildings where noise restrictions exist. They are simply cranked up by the operator to access the work area.

Powered vertical low-level access lifts combine height and reach with low ground bearing pressure, making them optimal for use on sensitive floors and when the need to move them between floors using elevators is required. Where power is required, these lifts help boost productivity during finishing work or routine maintenance in indoor spaces.

It’s also important to note that low-level access equipment helps with worker fatigue. With ladders, a worker must climb up and down to get the tools he or she needs. It can be exhausting work and can lead to an increased risk of falls or injuries. However, low-level access equipment offers trays to stow tools that allows for work to get done more quickly.

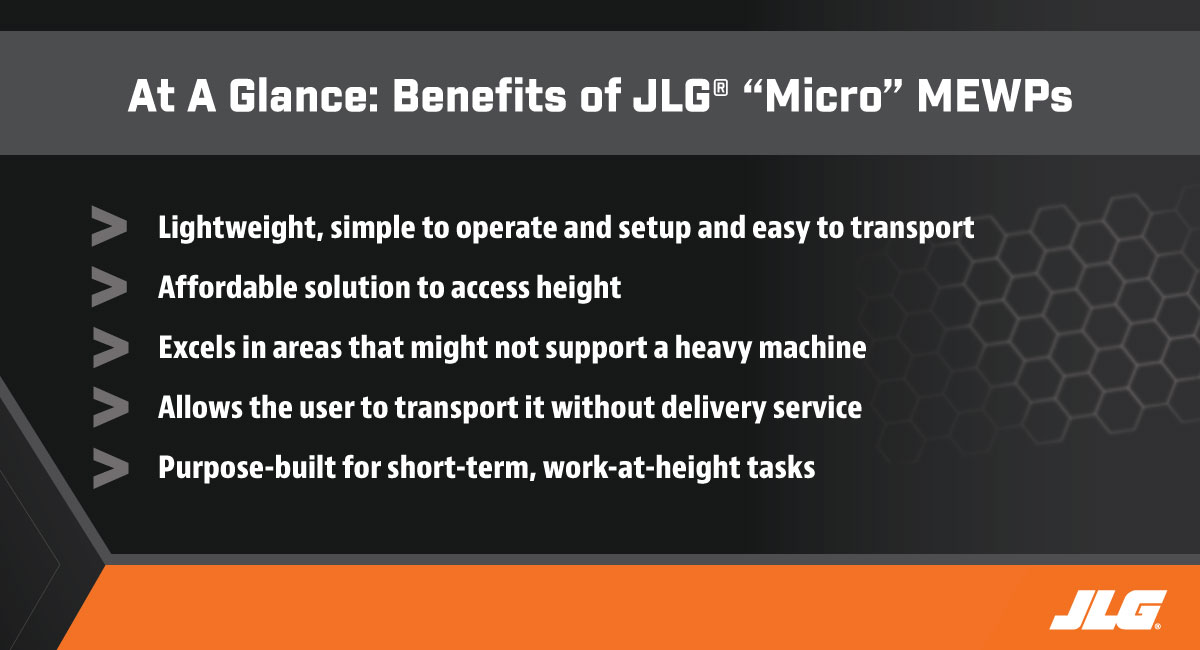

What advantages do micro MEWPs offer? What are the primary applications for their current use?

Low-level access lifts offer a safer alternative to ladders and scaffolding that can help mitigate the risks associated with working at height while reducing worker fatigue and enabling ergonomic working positions. For example, they can replace a range of ladders, including single-sided stepladders, twin stepladders, podium stepladders and platform stepladders, as well as be used in place of stationary and rolling scaffolding.

And, these types of machines are lightweight and compact in size. They are easily pushed into place or between work areas and require nominal storage space, making them ideal for ongoing facility maintenance from airports to data centers to high rise buildings and just about anything in between. Additionally, they are used on construction sites for fit out and finish work, such as painting, installing fire alarm or sprinkler systems, putting in (or replacing) lighting and ceiling tiles, as well as other similar type of tasks.

The most common applications for low-level access lifts include:

- Performing facility maintenance in healthcare, education, data centers and office settings

- Completing contractors’ tasks like drywall work, painting, HVAC installation and electrical/mechanical work

- Refitting retail displays and updating seasonal décor

- Maintaining production equipment in manufacturing environments

What types of micro MEWPs does JLG offer?

Humans have used ladders and scaffolding for hundreds of years. But, JLG believes that it’s time to evolve by replacing these outdated tools with low-level access lifts — products designed to help workers comfortably reach tasks at heights up to 20 ft.

JLG has been known as a leading manufacturer of machines for accessing extreme heights, but we also offer a family of machines that applies the same safety and productivity standards to lower heights. In this category, JLG offers several different types of low-level access MEWPs, including battery powered scissor lifts and vertical lifts as well as human-powered vertical lifts. JLG® products that fit within the “micro” MEWPs category are the ES1330 and ES1530 scissor lifts, as well as EcoLift 50 and EcoLift 70 manually operated lifts, as well as the 830P and 1030P push around lifts. For more information on these JLG products, click here.

Want to stay up to date with industry news and trends similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.