Jonathan Shapiro

Jonathan Shapiro

Senior Manager, ClearSky Telematics Sales and Business Development

____

JLG Industries

Did you know that telematics in construction equipment has been around for more than 20 years?

Large mining equipment manufacturers were among the first companies to introduce the technology, and contractors and end-users quickly saw the benefits — maximum uptime, cost savings on service, equipment security and increased productivity, to name a few.

Today, it is rare to meet with someone in the construction equipment rental business or individual equipment owners who would say they aren’t aware of telematics — but, there are still plenty of fleet managers who have yet to begin taking advantage of this technology. In fact, estimates show that only 20-30 percent of equipment fleet companies are currently leveraging telematics on their fleet.

So, why is it taking so long for the remaining construction sectors to adopt telematics?

There are many reasons why construction equipment companies have been late-adopters of telematics. Some had up-front investment concerns, spurred by a general lack of understanding, others expressed the fear of managing the data and the anxiety over related IT concerns. All of which have eased over time as systems have become more commonplace.

Telematics doesn't need to be complicated or costly.

Telematics doesn’t need to be complicated or costly. In most cases, while the data points can be endless, and perhaps provide more detail than most would initially need, not all the information needs to be used at the same time. Fleet managers can easily fine-tune the data into workable amounts that can later be enhanced as IT skills improve or the decision is made to hire technical experts.

Benefits of telematics

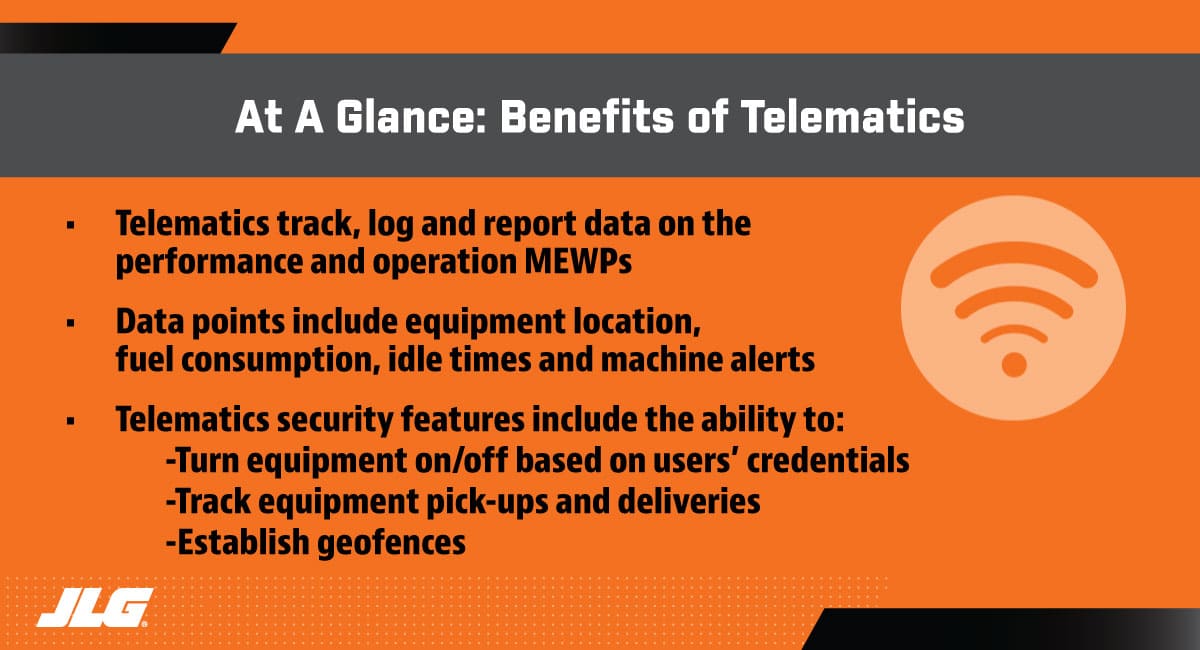

Today’s telematics systems typically combine GPS technology, diagnostics and monitoring sensors to track, log and report data on the performance and operation of construction equipment, including aerial access machines like mobile elevating work platforms (MEWPs) and telehandlers. The data can provide high-level, or finite details, on a number of machine systems, including equipment location, fuel consumption, idle times and machine alerts.

As telematics data becomes more manageable, fleet managers can easily see the benefits of using these systems to enhance their daily operations. For example, telematics can help fleet managers more accurately manage the service needs of their fleet, therefore keeping equipment running longer which translates into major returns on uptime, reliability, productivity and profitability.

Telematics can be a major driver in boosting the performance of equipment, as well as a catalyst for keeping workers busy and meeting deadlines.

For example, over the course of a construction project’s lifecycle, more than 40 percent of time can be wasted looking for equipment and materials. A telematics solution can theoretically cut that number down to zero. So, even at the most basic level of use — GPS location of equipment — the technology improves efficiency on job sites.

Telematics has many uses

Telematics technology is much more advanced than most realize, and it can have a significant impact across the entire construction project.

For instance, with some brands, telematics can provide fleet managers with the ability to turn equipment on and off based on an operator’s safety credentials — a good example of this is the JLG® ClearSky™ Access Control feature. Also, most telematics systems offer security features that cut down on theft, as well as the ability to track delivery of equipment from the time it leaves the equipment yard to when it arrives on site. And, many can even establish geofences, or invisible lines drawn by GPS coordinates, set up to keep equipment from being operated outside approved areas of the job site. This confinement of use enhances safety on the site by keeping equipment where it’s been approved for operation.

With telematics, fleet managers have the ability to monitor which machines are being used, how long the equipment is operating each day and the critical advantage of easily monitoring battery usage, including whether or not equipment has been plugged in for charging at the end of the day.

Telematics is not something to be feared. Job sites only are expanding in size and complexity, which makes meeting project deadlines increasingly important. All of these facets of telematics can greatly improve productivity on a job site, often helping projects to stay on target for completion — or helping to proactively plan for delays.

You can learn more about telematics solutions offered by JLG here.

Want to stay up to date with industry news and trends similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.