Within the last few years, JLG has taken big leaps in the evolution of our scissor lift portfolio, incorporating some exciting new design changes and adding in new specialty models.

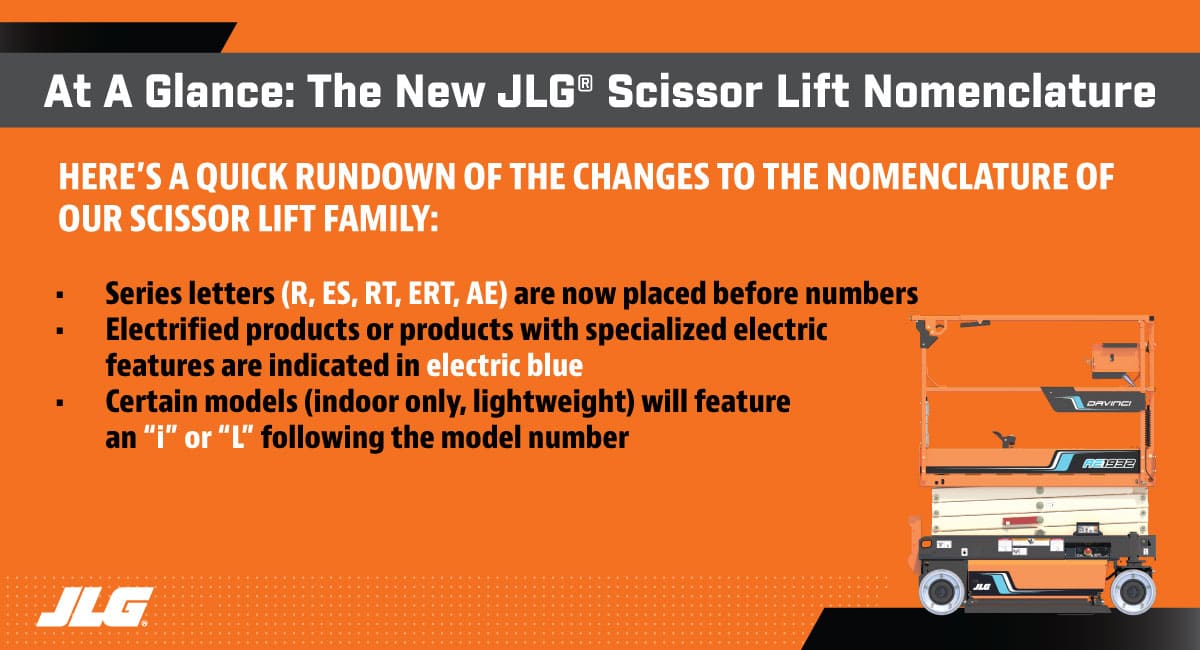

All of these changes led us to developing an intuitive, standardized naming system that ensures consistency across the JLG® scissor lift product line and enables users to match the right machine to the application.

Now that these scissor lifts are available in the market, we want to offer you a few insights to help you decipher our new nomenclature.

What has changed in the product name?

New JLG scissor lifts are now labeled to be a better guide when evaluating different models so customers can select the one that’s right for their job site needs. Let’s use the ES1330L model as an example.

The prefix — ES — indicates the series name and category. In this case, ES stands for “electric-drive scissor lift.”

If the prefix is colored — for instance, if the ES is in electric blue – this indicates an electrified product or a unique electric feature, in this case, electric drive.

The first two numbers — 13 — denotes the model’s platform height in feet. The second two numbers — 30 — denotes the platform width in inches.

The suffix lets you know what type of specialty model it is, such as an indoor-only (i) or a lightweight model (L).

Additional design elements, like the letter designation of the machine, have also been included to help you easily identify which models are ANSI A92.20/CSA B354 compliant machines. Any machine that has the family name in the prefix complies with the updated North American standards.

That said, there may be compliant machines in the field that do not use this new nomenclature because they were manufactured before we officially launched this standardized naming system. When in doubt, refer to the nameplate — it is the source of truth on all JLG machines.

Why have we done this?

Some of the changes we’ve made to our scissor lift line were in response to the updated ANSI and CSA standards, adding in features that the industry needs. But we just didn’t engineer these equipment additions to meet the standards, our goal was to exceed them.

We did this by including intuitive design elements to signify compliance. Some of these changes are:

- Kick plates around the full platform

- Replacing chain gates with self-closing gates

- Similar to European models, all models now include caution tape on the extension

- All 19-ft models will have a quick fold down rail system available, standard on ES series models and optional on R series models

Why do these changes matter?

For quite a few reasons, actually.

First, our expanded scissor lift offering now integrates brand new, specialized models, including lightweight and indoor-only options into our field-proven family.

Second, many of the progressive design changes were customer-driven and reinforce our company’s legacy of putting user safety first.

Third, we wanted to make sure our products provide you a simplified service and a similar experience for operators, regardless of what machine they are using, which in turn simplifies training and improves the overall experience with JLG equipment. You can see this in our updates through visual design cues and an intuitive naming system that make customer-service communications easier and more straightforward.

Last but not least, by adding continuity across our different scissor lift lines we have been able to shorten the learning curve for technicians and operators to become familiar with these new machines. And in simplifying certain design elements and using common parts across all models, we have been able to make preventive maintenance tasks and field service repairs more streamlined and efficient to complete.

Why are these changes important to you?

All of these changes mean that JLG scissor lifts continue to be purpose-built to meet your job site needs now — and in the future.

You can find more information about JLG scissor lifts, here.

Want to stay up to date with industry news and trends similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.