JLG Industries, Inc.

JLG Industries, Inc.

World-leading access equipment manufacturer

____

McConnellsburg, PA

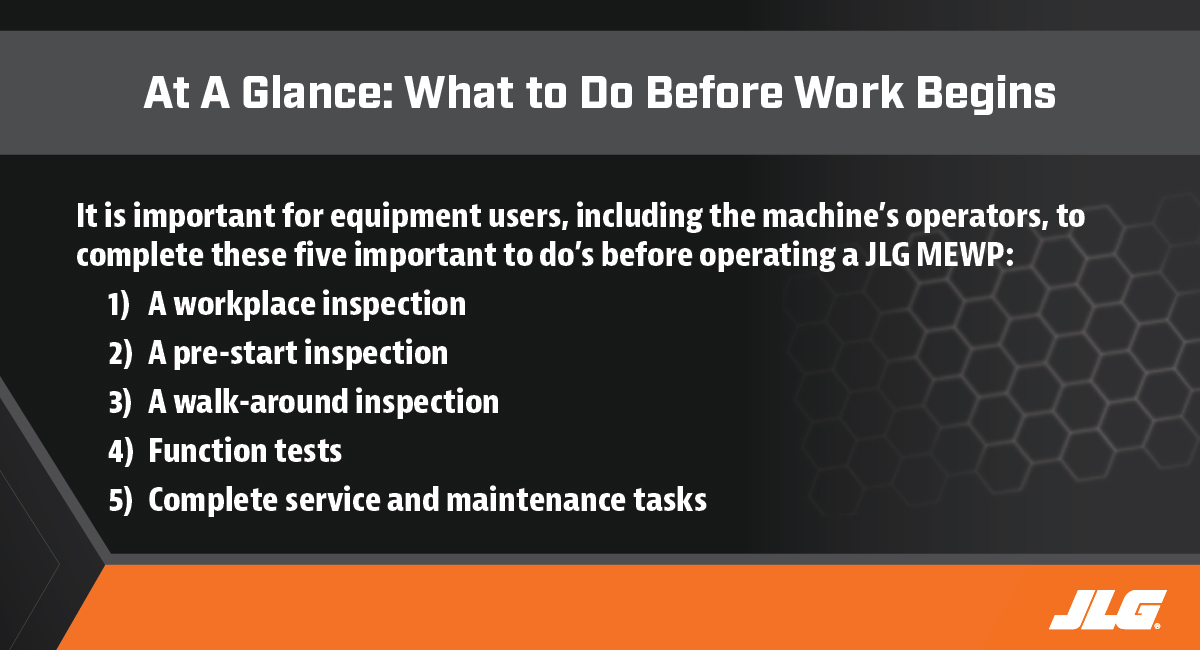

Before operating JLG® mobile elevating work platforms (MEWPs), which includes all models of the brand’s boom lifts, scissor lifts and low-level access lifts, it is important for equipment users, including the machine’s operators, to complete these five important things:

- A workplace inspection

- A pre-start inspection

- A walk-around inspection

- Function tests

- Complete service and maintenance tasks

Below is a little bit more information about each of these tasks. Additional details can be found in a machine’s Operation and Safety Manual. Manuals for JLG MEWPs can be accessed here or in the technical publications section on OnlineExpress, the companies online parts purchasing system and resource center.

#1: Workplace Inspection

Before and during operation, JLG MEWP users must take precautions to avoid all hazards in the work area. This includes a check of the work area for overhead hazards, such as electric lines, bridge cranes and other potential overhead obstructions.

And, check the operating surfaces for holes, bumps, drop-offs, obstructions, debris, concealed holes and other potential hazards.

Also, make sure that the ground conditions are adequate to support the maximum tire load (indicated on the tire load decals on the machine’s chassis, adjacent to each wheel). It is important to not travel on unsupported surfaces.

Finally, check the work area for hazardous locations. The machine should not be operated in hazardous environments, unless approved by JLG for that purpose.

#2: Pre-Start Inspection

Before turning on any JLG MEWP, a pre-start inspection of the machine should be conducted to ensure that the machine is safe to operate. It will also help to uncover any discrepancies with the machine that indicate maintenance services are needed — catching small issues early before they result in unscheduled downtime and expensive repairs.

This type of inspection includes, but is not limited to, the following items:

- Cleanliness – Check all surfaces for leakage, debris, slippery substances and/or foreign objects

- Structure – Inspect the machine’s structure for dents, damage, weld or parent metal cracks, as well as any other discrepancies

- Platform Gate – Verify the gate closes properly

- Lanyard Attach Points – Check the condition of all authorized lanyard anchorage points

- Decal & Placards – Check all for cleanliness and legibility, make sure none are missing. Clean or replace as needed

- Operation & Safety Manuals – Make sure a copy of the Operation and Safety Manual, AEM Safety Manual and ANSI Manual of Responsibilities is enclosed in the weather-resistant storage container

- Battery – Charge as required

- Fuel – Add the proper fuel, as necessary

- Engine Oil – Make sure the oil level is at the Full mark on the dipstick

- Hydraulic Oil – Check the hydraulic oil level, add as required

- Walk-Around Inspection – Perform as instructed by the machine’s Operations and Safety Manual

- Function Check – Following the walk-around inspection, perform as instructed by the machine’s Operations and Safety Manual

A pre-start inspection should also include a check to make sure that all safety devices are operating properly, as well as a check for modifications to the machine’s components. It is important at this point to verify that any modifications on the machine have been approved by JLG in order to avoid safety violations.

If the machine is equipped with accessories and/or attachments, please refer to the machine’s Accessories section in the Operations and Safety Manual, or look at the accessory installed on the machine, for specific inspection, operation and maintenance instructions

#3: Walk-Around Inspection

Access equipment gets a lot of use throughout the work week, and things do happen — items get damaged, cracked or worn out. These discrepancies may start out small, and may not even be noticeable at first, but over time, as they get bigger, they could affect the safe operation of the machine. Taking time each day to do a 360-degree walk-around of the machine will help locate these discrepancies as soon as possible.

The walk-around needs to include a thorough, visual inspection of all the machine’s critical components, including (but not limited to) the chassis, engine compartment, electrical connections, scissor stack or boom assembly, control systems and stations and so on, prior to operation. A machine’s Operations and Safety Manual is the best resource to consult on how to conduct a proper walk-around inspection.

#4: Function Tests

Once the walk-around inspection is completed, perform a function check on all the machine’s systems to make sure they are operating properly. These should be done in an area free of overhead and ground level obstructions.

On JLG MEWPs, function tests are performed by the equipment operator from the machine’s ground console, then from the platform control console and with the machine in stowed position — always refer to the machine’s Operations and Safety Manual for specific tests to complete.

#5: Complete Required Service & Maintenance Tasks

For the safe use of JLG MEWPs, machines should not be operated until all of the inspections and functional tests have been performed as specified. By not performing pre-operation to do’s, equipment owners and operators could easily be overlooking some obvious, or even serious, machine problems.

If during any of these inspections or functions tests the machine does not operate properly, it should be shut down immediately and reported to proper maintenance personnel. A JLG MEWP should not be operated until the machine has been declared safe for operation. That means that any service and maintenance required should be done, according to the machine’s Service & Maintenance Manual, before the machine is operated again.

Do you want to stay up-to-date with industry news and issues similar to this? Make sure you subscribe below to receive monthly updates from #DirectAccess with newly posted content so you never miss important information.