An increasing demand for compact equipment and higher capacity equipment are just a few of the trends we saw in 2020. And, aerial equipment manufacturers like JLG are continually evolving and introducing new products and the associated technologies and features to meet these growing customer needs.

As a company, JLG is working at elevating the access industry and our product line in three core areas: Safety, Productivity and Technology. We listen to the needs of our customer then innovate based on their input. We call this customer inspired innovation, and it drives everything we do.

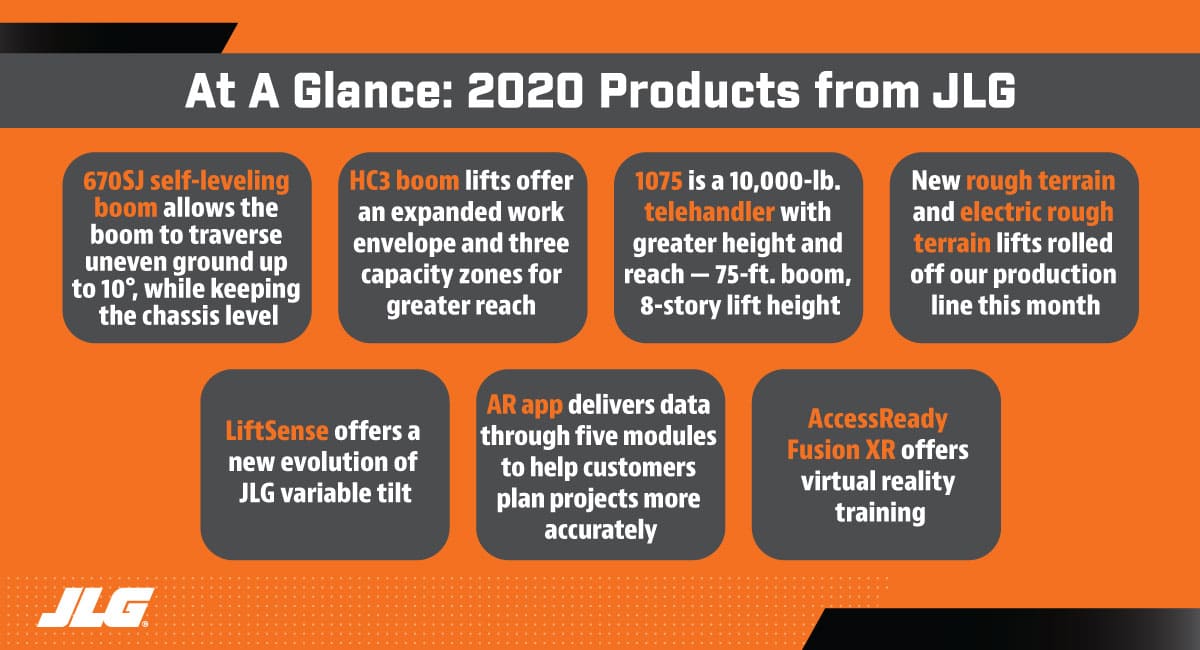

Here is a recap of the latest JLG® products launched in 2020…

Our signature launch at CONEXPO-CON/AGG 2020 was our 670SJ self-leveling boom lift. JLG engineers recognized that traditional boom lifts were designed for the near ideal conditions of firm, flat surfaces. Since the world is neither flat, nor does much of it come with improved surfaces, they began exploring the viability of a boom lift with a smart suspension. The result is our new 670SJ self-leveling boom, which allows the boom to traverse uneven ground up to 10°, while keeping the chassis level. This results in decreased platform movement during travel for greater operator comfort and confidence and full functionality while driving at height for greater productivity.

The JLG line of HC3 (HC stands for High Capacity and the 3 for zones and people) boom lifts offer an expanded work envelope and three capacity zones for greater reach than comparable models. Thus far we have released 40-ft., 60-ft., and 80-ft. models. Each offers an unrestricted capacity zone, plus two restricted capacity zones — allowing operators to bring more tools, material and people to the work area. All JLG high-capacity boom lifts are rated for up to three occupants in all three zones.

On the telehandler front, customers told us they wanted a 10,000-lb. telehandler with greater height and reach. We developed the JLG 1075, 75-ft. boom, 8-story lift height telehandler as a result. It delivers a full two stories more lift height than comparable models and offers a 60-ft reach so operators can place materials exactly where they are needed, minimizing rehandling. This new telehandler has the advantages of a crane without the high, associated rental and assembly costs. New attachments like our sheet material handler make it even more versatile, as it allows the unit to reach further into buildings to improve productivity.

We’ve got quite a few new scissor lift offerings, including our new line of rough terrain and electric rough terrain lifts which rolled off our production line this month. This new family of scissors is 69-in. wide and comes in 26-, 33-, 40- and 47-ft. platform heights. All boast an industry-leading platform size, with the ERT 4769 being the tallest scissor in its size class. The 47-ft platform height on the RT4769 and ERT4769 provide up to a 5-story work height, a feature that is becoming more and more important as buildings become more vertical in nature.

All models are available with a diesel engine or a battery power source and electric drive, and these units come with several productivity-enhancing features, including indoor/outdoor drive at height capabilities. This feature is particularly useful during warehouse construction, which requires installation of utilities at a fixed height across the length of a building.

LiftSense, an evolution of JLG variable tilt, monitors both the weight in the platform and the machine’s tilt to determine the allowable work envelope. This new and industry-first feature notifies the operator prior to raising the machine how high they can elevate, removing the guesswork that often results in having to descend and try again. QuikLevel Advanced allows the stowed scissor to level on a side slope up to 5° with driving at full height allowed under certain conditions. This is especially beneficial when performing work at height along the outside of a building that has been graded for drainage at a consistent slope.

These new rough terrain scissors also include the industry’s first LCD platform control box. This intuitive display delivers a multitude of productivity, terrain, machine health and safety notifications to the operator during use.

From a technology standpoint, we are looking beyond the product. We are working to develop digital solutions and tools that are useful on the job site to further improve safety and productivity.

One example is our Augmented Reality (AR) app, which delivers data through five modules to help customers plan projects more accurately. The five modules include machine visualization, kit visualization, operational guidance, a decal viewer and inspection assistance. The visualization tools allow the user to choose the right equipment and/or accessory for the job by placing and moving a virtual machine or accessory onto a machine in an actual work environment. The operational guidance and decal viewer help users understand the machine controls and decals in their local language, while the inspection assistant provides historical inspection data specific to the machine.

And last, but not least, is the extension of our virtual reality training with AccessReady Fusion XR™. This offering combines JLG’s original boom lift training simulator with a full scissor lift training package, giving operators the opportunity to become familiar with each MEWP type and its controls prior to stepping into an actual machine. It provides an immersive, virtual reality-based training for users of all skill levels. Instructors can create their own scenarios designed to test various skills and select the criteria for evaluation of user performance. As you can see, JLG’s commitment to advancing training either in-person, online or virtually remains as strong as ever.

You can find more information about JLG products here.

Want to stay up to date with industry news and trends similar to this? Make sure you subscribe below to receive monthly updates from Direct Access with newly posted content so you never miss important information.